Mathematical and Computer Modeling of Technological Parameters of Anaerobic Fermentation in Bioreactors

Article Information

Kapan Shakerkhan1*, Vladimir Meshechkin3, Zhazira Taszhurekova2*, Ermek Abilmazhinov1, Ainur Abduvalova4

1Department of physics and informatics, Shakarim University, Glinka 20A, Semey, Kazakhstan

2Department of Applied Informatics and Programming, Dulaty University, Taraz, Kazakhstan

3Institute of Digital, Kemerovo State University, Krasnaya 6, Russia

4Department of Department of Information Systems, Dulaty University, Taraz, Kazakhstan

*Correspondingautor 1: Kapan Shakerkhan, Department of physics and informatics, Shakarim University, Glinka 20A, Semey, Kazakhstan.

*Correspondingautor 2: Zhazira Taszhurekova, Department of Applied Informatics and Programming, Dulaty University, Taraz, Kazakhstan.

Received: 06 November 2025; Accepted: 14 November 2025; Published: 02 February 2026

Citation: Kapan Shakerkhan, Vladimir Meshechkin, Zhazira Taszhurekova, Ermek Abilmazhinov, Ainur Abduvalova. Mathematical and Computer Modeling of Technological Parameters of Anaerobic Fermentation in Bioreactors. Journal of Biotechnology and Biomedicine. 9 (2026): 01-04.

View / Download Pdf Share at FacebookAbstract

This research article examines computer and mathematical modeling of anaerobic digestion in livestock waste recycling. Several approaches to mathematical modeling of anaerobic digestion processes are considered, including ADM1 modeling. The creation of a computer program based on a self-developed mathematical model is described. A mathematical model of anaerobic fermentation has been proposed, which has proven its efficiency and reliability under industrial-scale conditions. This mathematical model was developed based on regression analysis and general correlation, with the identification of empirical relationships between biogas yield and 20 different process parameters that are measured by appropriate biosensors during industrial production. The mathematical model we developed, taking into account a small volume of static data, and in our case for 5 positions of measured values, showed an average approximation error equal to 5.5% and a determination coefficient equal to 0.95, which proves to us a lower error, a high-quality and accurate measurement indicator. In this regard, the computer and mathematical model of anaerobic fermentation under industrial scale conditions that we proposed is considered effective and practical. The computer program was developed taking into account the concept of online statistical data transmission, using cellular communications and the Internet, and processing large amounts of statistical data, i.e., the Big Data concept. Flexibility, scalability, and accuracy are also considered. Machine learning technologies are proposed for using with this computer program, based on Big Data concepts.

Keywords

Mathematical modeling; Efficient energy; Correlation and regression analysis; Web programming; Big data processing

Mathematical modeling; Efficient energy; Correlation and regression analysis; Web programming; Big data processing

Article Details

The relevance of this work is determined by the current active implementation of alternative energy sources, one of which is the development and operation of bioenergy complexes. These systems not only provide energy and heat but also protect the environment from methane emissions, which naturally occur during the decomposition of biowaste from agriculture and the food industry. To ensure the widespread use of these technologies, it is necessary to develop an effective system for managing and predicting the technological processes occurring in these systems [1].

The novelty of the work is related to the creation of a computer program and a mathematical model for describing the technological parameters of a bioreactor during anaerobic fermentation under production, industrial-scale conditions in real time. Currently used models, such as the Konto, Mono, Chen-Hashimoto models, the international model of anaerobic fermentation ADM1, etc., are general and of little usage in production, since they describe the biochemical, physicochemical and kinetic processes of reproduction of anaerobic bacteria and their inhibition under laboratory conditions. Therefore, such mathematical models are difficult to use in practice. Furthermore, parameters such as bacterial concentration and inhibition coefficient are immeasurable in real-world production conditions. An analysis of the work of scientists from around the world shows that a scientific methodology for calculating bioreactor parameters for anaerobic fermentation in industrial settings has not previously been studied or applied [2].

Our research to develop a mathematical model for more accurately predicting biogas yield during anaerobic digestion used statistical data from a biogas plant in Kurma, Karaganda region, and data from a biogas plant in Manitoba, Canada. The proposed mathematical model included more than 20 different parameters that significantly affect the quality of anaerobic fermentation and, accordingly, the biogas yield. These parameters include indicators of the amount of macro- and microelements, as well as the main process factors: K – potassium, Na – sodium, Ca – calcium, Mg – magnesium, Fe – iron, Cu – copper, Zn – zinc, Ni – nickel, Co – cobalt, Mo – molybdenum, Cr – chromium, Cd – cadmium, C – carbon, N – nitrogen, P – phosphorus, C/N – carbon to nitrogen ratio, L – nutrient concentration, n – degree of grinding, VFA – fatty acid content, τ – fermentation period, m – substrate mass, t – temperature, pH – acidity index, φ – humidity, S – sulfur, H4N+ – ammonium [3, 4].

Experimental researches have shown that the influence of various parameters on biogas yield is linear. Therefore, the resulting mathematical model is a linear equation of empirical relationships between parameters, obtained through regression analysis.

Based on statistical data, a number of mathematical models were created, differing in the number of factors taken into account, which were included based on the level of correlation with the biogas yield indicator [5].

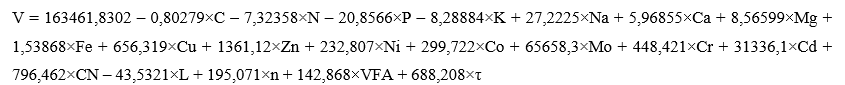

The best result was shown by a model in the form of a linear regression equation with twenty factors:

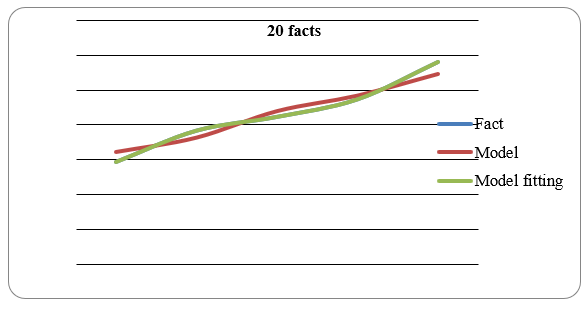

The calculation results are presented in figure 1. The multiple correlation coefficients between V and the factors under consideration were 0.84, and the average relative error of the constructed model was 5.47% [7, 11].

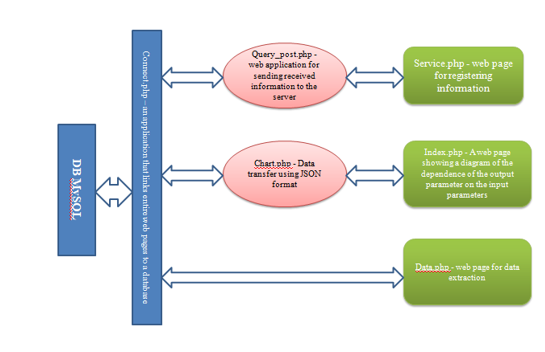

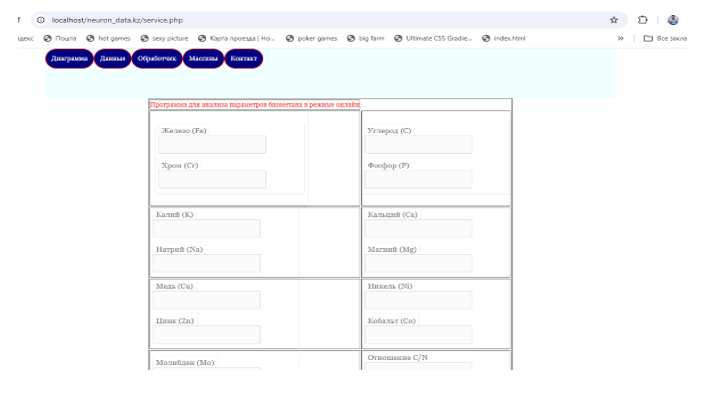

To create the computer program, the hypertext markup languages HTML, CSS, scripting languages PHP, Javascript, and the MySQL database were used. This web technology was not chosen by chance, as its concept is based on the visualization of statistical data using the Internet and mobile devices, which allows experts to obtain information remotely in real time. To implement this concept, a website was developed that allows online transfer of measured values to a database (DB) and obtaining calculation results (see fig. 2, 3) [6, 8].

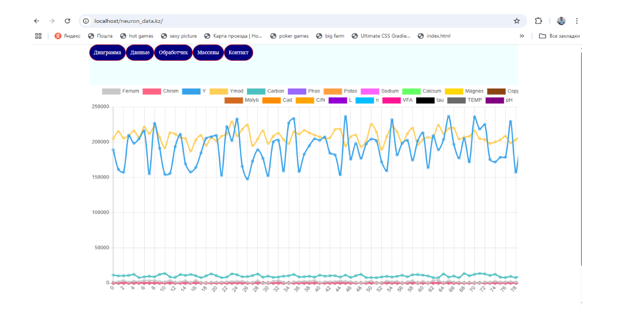

All statistical data obtained during the operation of the bioenergy plant are collected and stored in a database. Next, using a computer program, we can process all this data and display it on the screen in the form of infographics. All data in the database can be displayed on the screen as shown in figure 4. [9, 10]

As a result of the research conducted, the following results were obtained:

- A comparative analysis of various mathematical models used in anaerobic fermentation research was performed, and their advantages and disadvantages were examined;

- The universal mathematical model for predicting anaerobic fermentation processes at an industrial scale was developed;

- The correlation coefficient R, the determination coefficient R2, and the average relative error A were determined, which suggest that the proposed model is sufficiently accurate and universal;

- Based on the constructed model, a computer program was created for predicting the operating results of bioenergy plants using HTML, CSS, PHP, JavaScript, and the MySQL database;

- The website was developed that allows for online transfer of measured values to a database and the necessary calculations.

Thus, the proposed mathematical model allows for more precise prediction of biogas yield during anaerobic fermentation on an industrial scale. This model can be applied not only to agriculture but also to other areas of human activity involving the processing of biowaste. It is designed taking into account parameters measured in real time at the production site using various biosensors. A computer program created based on the proposed mathematical model, using an analytical database and machine learning technologies, will eventually enable forecasting the operation of a bioenergy plant and calculating its efficiency and productivity, taking into account various influencing factors.

Funding

This study was funded by the Scientific Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (grant no. AP25794135).

References

- Modeling Of The Anaerobic Digestion Of Organic Waste For Biogas Production. Fedailaine M, Moussi K, Khitous M, Abada S, Saber M, Tirichine N. The 5th International Conference On Sustainable Energy Information Technology (2015).

- Review of the mathematical description of the process of methanogenesis in a bioreactor. Tlebaev M, Kalinchun N, Dzhunbayeva G.

- Mathematical modeling of the process of obtaining biogas in the processing of biowaste. Kushchev L, Suslov D, Alifanova A, Nikulin N.

- Abilmazhinov ET, Akimzhanov AZh, Shaiakhmetov EY, et al. Development of the biogas industry and prospects for the implementation of biogas plants in Kazakhstan. Eurasian Physical Technical Journal 18 (2021): 76-82.

- LI, Ruzhinskaya, AA Fomenkova. Mathematical modeling the processes of anaerobic fermentation of an organic substrate.

- MB Tlebaev, NK Kalinchun, DU Mamataeva. Review of the mathematical description of the process of methanogenesis in a bioreactor. International scientific journal.

- O Sönmez, V Turan, C Kaya. The effects of sulfur, cattle and poultry manure addition on soil phosphorus. Turkish Journal of Agriculture and Forestry (2016).

- Energy-saving technology for processing cattle manure. Dissertation work / Ulan-Ude / 2016, V.P. Druzyanova.

- Substantiation of the parameters of a small-volume digester with a stirring device for the conditions of the Republic of Sakha (Yakutia). Dissertation work / Blagoveshchensk / 2017, E.N. Egorova.

- Stenin D, Stenina N, Akanov A, Sagindikov K. Digitalization and innovative development of mining processes. E3S Web of Conferences (2019).

- Operational Parameters of Biogas Plants: A Review and Evaluation Study. Abdullah Nsair, Senem Onen Cinar, Ayah Alassali, Hani Abu Qdais, Kerstin Kuchta. (2020).