Influence of Cookery Method on Frozen Ground Beef Patties

Article Information

Savannah L Douglas, Gabriela M Bernardez-Morales, Brooks W Nichols, Aeriel D Belk, Jase J Ball, and Jason T Sawyer*

Department of Animal Sciences, Auburn University, Auburn, AL 36849, USA

*Corresponding Author: Jason T Sawyer, Department of Animal Sciences, Auburn University, Auburn, AL 36849, USA

Received: 22 September 2023; Accepted: 05 October 2023; Published: 19 October 2023

Citation: Savannah L Douglas, Gabriela M Bernardez-Morales, Brooks W Nichols, Aeriel D Belk, Jase J Ball, and Jason T Sawyer. Influence of Cookery Method on Frozen Ground Beef Patties. Journal of Food Science and Nutrition Research. 6 (2023): 165-170.

View / Download Pdf Share at FacebookAbstract

Ground beef patties commonly known as hamburgers are a popular food item throughout the United States among meat consumers. Technologies for measuring changes in cooked and fresh characteristics of ground beef patties have improved, and the need for evaluating cooked meat patty characteristics are necessary. In the current study, ground beef patties were cooked from frozen using a griddle (GRID), convection oven (OVEN), or clam shell (GARL) to 71.1 °C. Cooked patties were evaluated for cook loss, cooking time, and objective tenderness (Allo-Kramer Shear Force). Patties cooked using the direct heat method GRID had the longest cooking time (p < 0.0001) compared to OVEN (p < 0.0001) and GARL (p < 0.0001) to reach 71.1 °C and the greatest percentage of cook loss versus OVEN (p < 0.0001) and GARL (p = 0.0223). In addition, patties cooked using the GRID required more Allo-Kramer shear force (p < 0.0001) and thus less objective tenderness compared to either OVEN (p < 0.0001) or GARL (p = 0.0988). Current results suggest that if frozen patties are cooked using various cookery methods, then the cooked characteristics are altered.

Keywords

Allo-kramer shear force; Cook loss; Cook time; Ground beef

Article Details

Introduction

The popular meat patty is manufactured from a combination of lean trimmings followed by grinding, blending, and forming ground beef. Most meat patties are comprised of ground beef and can be produced through grinding methods by manufacturers in a variety of textures that may affect consumer mouthfeel [1]. More importantly, ground beef patties remain a common staple in most diets; nearly 60% of consumers use ground beef as an ingredient and 50% consume ground beef patties weekly [2]. In 2021, it was reported that ground beef products comprised 48% of consumer sales and 37% of spent consumer dollars in the United States [2]. Of this, 38% of patties are consumed from fast-food restaurants and 33% are consumed at home [1].

Selecting a cooking method can alter the amount of water and fat lost during cooking and affect the tenderness of the cooked product. Tenderness is a trait that has been measured extensively for many decades and has been correlated to the eating quality of a particular product, especially red meat [4]. Tenderness can be a major determinant for consumers in their satisfaction of a product or likelihood of repeat purchases [5]. Furthermore, it has been well demonstrated throughout the literature that ground beef patties are recognized for palatability traits of juiciness, beef flavor, and even tenderness. When meat is cooked, proteins become weaker, which expels fluid from the muscle. Inevitably, this causes an issue with the water holding capacity which is also linked to the cook loss, or the amount of weight lost once a product has been cooked [6].

Cooking methods are instrumental in preserving the characteristics of quality within a meat product before eating occurs. In a previous study [7], cooking leads to a weight reduction of hamburger patties largely due to water loss during the cooking process. Greater moisture loss in ground beef patties has been reported to occur when indirect cookery methods such as roasting or microwaving are used [7]. This supports the idea that cooking methods influence the water holding capacity and cook loss which can then in turn impact the consumers perception of tenderness.

Undercooked ground beef has been linked to foodborne illnesses, specifically Escherichia coli O157:H7 [8,9]. To prevent such illnesses, it is recommended to cook ground beef to an internal temperature of 71 °C [10]. Various cookery methods can be used to prepare hamburger patties such as deep frying, infrared radiation, convection heating, and double-sided contact cooking are common in restaurants within the United States [11]. Each cookery method can change the overall quality attributes of texture, juiciness, color and palatability of the ground beef patty.

For the last two decades, it has been communicated that the internal color of a ground beef patty is not a reliable indication of determining safety and product temperature of ground beef patties [12]. In addition to the internal cooked color, thawing for an increased amount of time can lead to food safety concerns [16]. Some beef patties may have persistent pinking even after reaching an internal temperature of 71.1°C [13-15]. Persistent pinking may be a result of post-mortem muscle pH, storage temperatures, or cooking method. Consumers have been advised against consuming meat patties that remain pink after cooking [16]. Previously, it has been shown that thawing prior to cooking meat patties can eliminate the issue of a red or pink color internal color. More specifically, literature reports that thawed patties require less cook time, and have an increased brown appearance due to the conversion of myoglobin to metmyoglobin [16,17]. Additionally, frozen patties had a higher peak load for shear force testing compared to thawed patties resulting in less objective tenderness [16]. Cooking ground beef patties from a frozen state can be more convenient to a consumer such as those in a restaurant or a school food service setting [18]. As most research on ground beef patties dates back several decades, it is important to continue research on an important meat product, such as ground beef patties. Therefore, the objective of this study was to analyze the impacts of direct and indirect cooking methods on the objective texture, cook loss and cooking time of frozen ground beef patties.

2. Materials and Methods

2.1 Raw materials

Commercial crossbred cattle (N = 6) were procured from the Auburn University’s Beef Teaching Unit and harvested at the Auburn University’s Lambert-Powell Meats Laboratory (Alabama Establishment Number: 43-ME-4) using commercial meat processing standards under USDA humane slaughter standards. Carcasses were chilled at 2.0°C (± 1.0°C) for 24 hours. After chilling, carcasses were fabricated into wholesale subprimals using fresh beef USDA institutional meat purchase specifications (IMPS) [19]. For this study, fresh beef (n = 12) shoulder clods (IMPS 114) and (n = 12) chuck eye rolls (IMPS 116D) were removed, and subcutaneous fat was trimmed to not exceed 0.635 cm thick. The subprimals were combined as one block of meat totaling 140 kg. Trimmings were coarse ground once through a 9.525 mm plate (SPECO 400, Shiller Park, IL, USA) using a commercial meat grinder (Model AFMG-48, The Biro Manufacturing Company, Marblehead, OH, USA). Coarse ground beef was then ground once through a 3.18 mm plate (SPECO 400, Shiller Park, IL, USA) with a bone eliminator attached (SPECO 400, Shiller Park, IL, USA). After final grinding, ground beef was formed into 151 g patties using a food portioning machine (Hollymatic Corporation Model 54, Countryside, IL, USA). Formed patties were placed on trays lined with freezer paper (Kold-Lok KL18, Dixie Consumer Products LLC, Atlanta, GA, USA) and crust-frozen for 45 minutes at -22.2°C to facilitate packaging. Crust frozen ground beef patties were packaged individually into thermoforming vacuum packaging using a Reiser roll-stock packaging machine (Optimus OL0924, Variovac, Zarrentin, Germany). A total of 225 patties were portioned, packaged and randomly assigned to a cookery method (n = 75/method). Patties were sealed in a forming layer with an oxygen transmission rate of 0.8cc/sq. m/24hr, and a non-forming layer with an oxygen transmission rate of 1.0 cc/sq. m/24hr (WINPAK Ltd, Winipeg, Canada). The packaged product was stored in boxes in the absence of light at -22.2°C until laboratory analysis could be completed.

2.2 Proximate analysis & pH value

Ground beef used in manufacturing patties was measured for proximate analysis using a near-infrared (NIR) approved spectrophotometer (Food Scan™, FOSS Analytical A/S, Hilleroed, Denmark), and data processing was determined using ISIscan™ Software (Santa Clara, CA, USA). Ultimate pH of ground beef was measured by weighing 2g into a plastic centrifuged tube, adding 20mL of deionized water and homogenizing (Kinematica CH-6010, Brinkmann Instruments, Inc., Westbury, NY, USA) for 45 seconds. Homogenized ground beef pH was measured using a pH meter (Model-HI99163, Hanna Instruments, Woonsocket, RI, USA) equipped with a glass electrode. The pH meter was calibrated (pH 4.0 and pH 7.0) using 2-point standard buffers (Thermo Fisher Scientific, Chelmsford, MA, USA) prior to sampling (Table 1).

|

pH |

Moisture1 |

Protein2 |

Fat3 |

Collagen4 |

|

5.712 |

66.81 |

22.04 |

18.13 |

3.742 |

1Moisuture percentage (g/100g). 2 Protein percentage (g.100 g). 3 Fat percentage (g/100 g). 4 Collagen percentage (g/100 g).

Table 1: Proximate analysis and ultimate pH level of raw ground beef trimmings.

2.3 Cookery method and cook time

Patties (n = 225; 75/treatment) were assigned randomly to one of three cookery methods that included a commercial cooking griddle (GRID; Model HEG36E-1, Vulcan, Baltimore, MD, USA), commercial convection oven (OVEN; Model VC3ED, Vulcan, Baltimore, MD, USA), or clamshell grill (GARL; Model XPE12, Garland Commercial Ranges, Ontario, Canada). Prior to cooking patties, each cookery method was pre-heated to 148.8°C. Internal temperature of each patty was monitored using a thermocouple placed into the geometric center of the patty until an internal temperature of 71.1 °C (Therma K-Plus, American Fork, Utah, USA) was reached. Patties cooked using the GRID and OVEN method, were flipped once reaching an internal temperature of 27°C. Cooking time of each patty was recorded, and cooked patties were removed, placed onto a wire-rack and cooled to room temperature 24.4 C.

2.4 Cook loss

Prior to cooking, patties (n = 225; 75/treatment) were removed from packaging and weighed on a calibrated scale (Model PB3002-S, Mettler Toledo, Columbus, OH, USA) to determine raw product weight. Once cooked as previously described, patties were cooled to room temperature and cooked weights were recorded. Cook loss percentage was calculated with the following formula: [(weight of raw sample – weight of cooked sample) ÷ weight of raw sample × 100)].

2.5 Allo-Kramer shear force

Patties (n = 225; 75/treatment) were measured for objective tenderness using a 5-Blade-Allo-Kramer attachment Shear Force (AKSF) attached to a texture analyzer (Model TA-XT Icon, Texture Technologies Corp., New York). Patties were cooked and cooled to room temperatures as described above. From each patty a 6 × 9 sq. cm (l × w) cube was cut from the center and the tenderness of each patty (n = 75/cookery methods) was measured. A load cell of 30 kg and a speed of 3 mm/sec, sheared each sample once, and the maximum peak force recorded during analysis was reported as Newton (N) of shear force.

2.6 Statistical analysis

Data were analyzed using the GLIMMIX model procedures of SAS (version 9.2; SAS Inst., Cary, NC, USA). Least squares means were computed for all variables. When significant (p ≤ 0.05) F-values were observed, least-squares means were separated using pair-wise t-tests (PDIFF option). This experiment was a completely randomized design, the treatments (GRID, GARL, OVEN) were assigned to experimental units (patty) at random.

3. Results and Discussion

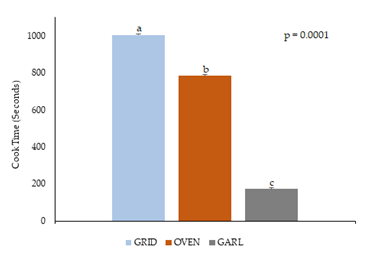

3.1 Cooking time

Analysis of cook time for the various cooking methods on frozen ground beef patties is presented in figure 1. Cooking time was impacted (p = 0.0001) by cooking method with GARL requiring the least amount of cook time (168 s) to reach an internal temperature of 71.1°C compared to GRID (1002 s) or OVEN (780 s) which proved to be significant (p < 0.0001). This was not surprising as the GARL method (p < 0.0001), which provides double-sided contact cooking and is commonly used in quick-service restaurants. The reduced cook time the GARL method provides can be beneficial in a quick-service restaurant where on average they are selling 4,500 burgers every minute [20]. Literature reports that mathematical models can be used to predict the change in temperature for cooking methods such as the clamshell grill as it has proven to be difficult to monitor temperature with the double-side cooking platens [21]. Additionally, it has been reported that ground beef patties containing an extra protein source require more cook time than those without [22]. Moreover, the fat percentage of the product can affect the cooking time. Beef patties containing more fat and less lean will require more time to reach an internal temperature of 71.1°C [23]. Great cooking times maybe the result of greater fat content in the patty. During cooking animal fat melts and dissolves at an increasing rate thus re-quiring less time to cook and reach an internal temperature of 71.1°C. Previous research on cooking times for the cooking methods used in the current study are limited. Therefore, more research is needed to identify the duration of cooking frozen beef patties to achieve an internal temperature of 71.1°C.

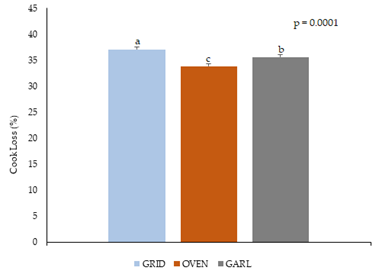

3.2 Cooking loss

Fresh meat can be comprised of almost 75% water and cooking greatly impacts the available moisture of a meat product. Analysis of the cook loss from each cooking method on frozen beef patties is presented in figure 2. Cook loss was greatest (p = 0.0001) in patties cooked using the GRID. However, both OVEN and GARL (p = 0.0107) both resulted in moisture loss after cooking greater than 30%. GARL cooking method compared to GRID had 2% less cook loss (p = 0.0223). Furthermore, comparing GRID which had the most cook loss at 37% to OVEN (p < 0.0001) it is evident the OVEN cooking method has the most moisture retention. During the cooking process, proteins are denatured, water evaporates, and there is a loss of melted fat which leads to the reduction in cooked meat weight. Changes in moisture can be accredited to the cookery method and duration of cooking [8]. In contrast to the current results, a variety of protein patties were cooked using a microwave and a conventional oven. Results indicate that beef and chicken patties cooked in an oven had greater cook loss than those patties cooked in the microwave [24]. Additional research suggests that the cook loss of camel whole-muscle steaks in comparison with veal, was much greater when cooking with a microwave than conventional methods such as roasting and braising [25]. Furthermore, cooking frozen chicken breast fillets concluded that cooking from frozen without thawing increased the amount of cook loss [26]. It is plausible that due to direct heat from GRID and GARL caused greater amounts of evaporation and increased cook loss. Whereas cooking frozen patties in the OVEN had the least amount of cook loss but required longer cooking times. Regardless, it appears cook loss is negatively associated with water-holding capacity, and cooking directly from a frozen state can result in a reduced water holding capacity when compared to cooking from a thawed state [25,26].

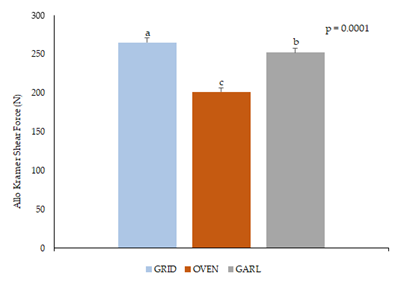

3.3 Allo-Kramer shear force

Objective tenderness of cooked patties was measured to identify variations in cookery method of frozen ground beef patties (Figure 3). Average value of force required to shear the sample was calculated. GRID = 265 N, GARL = 252 N, and OVEN = 201 N. Tenderness values were greater (p = 0.0001) in patties cooked using direct heat GRID and GARL. The lowest amount of force required to shear through the patty was from the OVEN cooking method compared to GARL and GRID (p < 0.0001). Previous literature on cookery method from fresh or frozen status is quite limited. More importantly, literature focused on ground beef patties centers on historical data nearly four decades ago. Improvements in technology and methods for measuring objective tenderness of meat products have been adopted throughout the industry and the need for identifying variations in cooking are warranted. Previous results suggest that lean trimming sources (young vs. old beef) or even mechanical obtained trimmings will alter objective tenderness of ground beef patties using a single blunt blade shear attachment [27]. Ground beef patty are a common consumer item, it is important to identify variation that can occur due to cooking to avoid consumer dissatisfaction. It is plausible that direct heat cooking of the patty resulted in greater moisture loss whereby causing objective tenderness values to increase. Previous literature on beef steaks cooked to varying end-points temperature or with varying methods have resulted in greater objective tenderness values [28]. Similar cooking methodologies using forced air (oven) or conduction (griddle) heat for steaks have been widely inconsistent for objective tenderness in either increasing or causing no differences in objective tenderness of longissimus steaks [29-32]. The reported differences in whole-muscle tenderness when using different cookery methods appear to be linked to the cooking duration of the selected method. Steaks cooked for a longer time have been reported to be more tender (objectively) than rapid cooking times [33]. Interestingly, cooking frozen patties has been reported to cause increases in objective tenderness [12]. This same trend was not identified in the current study which indicates that factors other than cook time are more important in ground beef in comparison to whole-muscle cuts. Cooking on the GRID or GARL from frozen likely caused a crust to form on the surface of the patty increasing the required force to shear through the patty.

4. Conclusions

Cookery method of frozen ground beef patties does directly influence cooking time, cook loss, and objective texture measurements. These results suggest that indirect heat (OVEN) cooking is the best of the evaluated cookery method for improved tenderness, minimizing cook loss and improving cooking yield. However, OVEN cooking required greater cooking times and may not be suitable for quick-service restaurant applications where GRID or GARL may be beneficial. However, more information is needed to fully capture the influence of cookery method on frozen and fresh ground beef patties. This preliminary study provided a brief snapshot of the influence cookery method elicits on meat quality, but future efforts are needed to determine the impact cookery method incurs on sensory attributes.

Author contributions

Conceptualization, S.L.D. and J.T.S.; methodology, S.L.D.; validation, S.L.D., and G.M.B.; formal analysis, J.T.S.; investigation, S.L.D. and G.M.B.; resources, J.T.S.; data curation, S.L.D and J.T.S.; writing—original draft preparation, S.L.D.; writing—review and edit-ing, S.L.D., G.M.B., B.W.N., A.D.B., J.J.B., and J.T.S.; supervision, J.T.S., project administration, J.T.S.; funding acquisition, J.T.S. All authors have read and agreed to the published version of the manuscript.

Funding

Partial funding of this project was supported by the Agricultural Research Service, U.S. Department of Agriculture under the Agreement No. 58-6010-1-005 and the Alabama Cattlemen’s Association Beef Research.

Data availability statement

Not applicable.

Acknowledgments

The authors would like to thank the staff of the Lambert Powell Meat Laboratory for assistance with fabrication of beef carcasses and manufacturing of ground beef patties.

Conflicts of interest

The authors declare no conflict of interest.

References

- Meat Patty Industry Analysis (2023).

- An Overview of Ground Beef at Retail and Foodservice (2023).

- How Many Pounds of Meat Can We Expect from a Beef Animal? (2023).

- Bolumar T, Toepfl S. Application of shockwaves for meat tenderization. Innovative food processing technologies 68 (2021): 231-258.

- Warner RD, Greenwood PL, Pethick DW. Genetic and environmental effects on meat quality. Meat Science 86 (2010): 171-183.

- James BJ, Yang SW. Effect of cooking method on the toughness of bovine M. semitendinosus. International Journal of Food Engineering 8 (2012): 256.

- Rodriguez-Estrada MT, Penazzi G, Caboni MF, et al. Effect of different cooking methods on some lipid and protein components of hamburgers. Meat Science 45 (1997): 563.

- Sheridan P, Shilton N. Analysis of yield while cooking beefburger patties using far infrared radiation. Journal of Food En-gineering 51 (2002): 3-11.

- Ahmed NM, Conner DE, Huffman DL. Heat resistance of Escherichia coli O157: H7 in meat and poultry as affected by product composition. Journal of Food Science 60 (1995): 606-610.

- Hague MA, Warren KE, Hunt MC, et al. Endpoint temperature, internal cooked color, and expressible juice color relationship in ground beef patties. Journal of Food Science 59 (1994): 465-470.

- Ground Beef & Food Safety (2023).

- Color of Cooked Ground Beef as It Relates to Doneness, USDA (2023).

- Trout GR. Variation in myoglobin denaturation and color of cooked beef, pork, and turkey meat as influenced by pH, sodium chloride, sodium tripolyphosphate, and cooking temperature. Journal of Food Science 54 (1989): 536-540.

- Van Laack RLJM, Berry BW, Solomon MB. Effect of precooking conditions on color of cooked beef patties. Journal of Food Protection6 (1996): 976-983.

- Van Laack RLJM, Berry BW, Solomon MB. Cooked color of patties processed from various combinations of normal or high pH beef and lean finely textured beef. Journal of Muscle Foods 8 (1997): 287-299.

- Bigner-George ME, Berry BW. Thawing prior to cooking affects sensory, shear force and cooking properties of beef patties. Journal of Food Science 65 (2000): 1-8.

- Van Laack RLJM, Berry BW, Solomon MB. Variations in internal color of cooked beef patties. Journal of Food Science 61 (1996b): 410-414.

- Berry BW. Cooked Color in High pH Beef Patties as Related to Fat Content and Cooking from the Frozen or Thawed State. Journal of Food Science 63 (1998): 747-934.

- United States Department of Agriculture. Fresh Beef Series, Institutional Meat Purchase Specifications (2020).

- The Truth About How Many Burgers McDonald’s Has Actually Sold (2023).

- Erdogdu F, Zorrilla SE, Singh RP. Effects of different objective functions on optimal decision variables: a study using modified complex method to optimize hamburger cooking. LWT - Food Science and Technology 32 (2006): 111-118.

- Ball JJ, Wyatt RP, Coursen MM, et al. Meat Substitution with Oat Protein Can Improve Ground Beef Patty Characteristics. Foods 10 (2021): 30-71.

- Zorrilla SE, Singh RP. Heat transfer in meat patties during double-sided cooking. Food Science and Technology Re-search 6 (2000): 130-135.

- Quitral V, Donoso ML, Jimenez P. Effect of conventional oven versus microwave cooking on rancidity, cooking loss and sensory difference of hamburger patties. Revista Chilena de Nutricion 47 (2020): 231-237.

- Nikmaram P, Yarmand MS, Emamjomeh Z. Effect of cooking methods on chemical composition, quality and cook loss of camel muscle (Longissimus dorsi) in comparison with veal. African Journal of Biotechnology 10 (2011): 51.

- Zhuang H, Savage EM. Comparison of cook loss, shear force, and sensory descriptive profiles of boneless skinless white meat cooked from a frozen or thawed state, Poultry Science 92 (2013): 3003-3009.

- Berry BW, Abraham HC. Sensory, shearforce and cooking properties of commercially processed ground beef patties. Food Quality and Preference 7 (1996): 55-59.

- Yancey JWS, Wharton MD, Apple JK. Cookery method and end-point temperature can affect the warner-bratzler shear force, cooking loss, and internal cooked color of beef longissimus steaks. Meat Science 88 (2011): 1-7.

- Wheeler TL, Shackelford SD, Koohmaraie M. Cooking and palatability traits of beef longissimus steaks cooked with a belt grill or an open-hearth electric broiler. Journal of Animal Science 76 (1998): 2805-2810.

- Lawrence TE, King DA, Obuz E, et al. Evaluation of electric belt-grilled, forced air-convection oven, and electric broiler cookery methods for beef tenderness research. Meat Science 58 (2001): 239-246.

- Kerth CR, Blair-Kerth LK, Jones WR. Warner-Bratzler shear force repeatability in beef longissimus steaks cooked with a convection oven, broiler, or clam-shell grill. Journal of Food Science 68 (2003): 668-670.

- Berry BW. Tenderness of beef loin steaks as influenced by marbling level, removal of subcutaneous fat, and cooking method. Journal of Animal Science 71 (1993): 2412-2419.

- McKenna DR, King D, Savell JW. Comparison of clam-shell cookers and electric broilers and their effects on cooking traits and repeatability of warner-bratzler shear force values. Meat Science 66 (2003): 225-229.