Influence of Baking Conditions on Bread Characteristics and Acrylamide Concentration

Article Information

Tzvetelin Dessev1*, Valérie Lalanne2, Javad Keramat3, Vanessa Jury2, Carole Prost2, Alain Le-Bail2

1University of Food Technologies, Plovdiv, Bulgaria

2ONIRIS, UMR CNRS GEPEA 6144, BP 82225, F-44322 NANTES Cedex 3, France

3Isfahan University of Technology (IUT), Department of Food Science and Technology, Isfahan, Iran

*Corresponding Author: Tzvetelin Dessev, University of Food Technologies, Plovdiv, Bulgaria

Received: 21 August 2020; Accepted: 10 September 2020; Published: 30 November 2020

Citation:

Tzvetelin Dessev, Valérie Lalanne, Javad Keramat, Vanessa Jury, Carole Prost, Alain Le-Bail. Influence of Baking Conditions on Bread Characteristics and Acrylamide Concentration. Journal of Food Science and Nutrition Research 3 (2020): 291-310.

View / Download Pdf Share at FacebookAbstract

The effect of baking temperature (vault and hearth) and steam injection on bread characteristics and acrylamide content was investigated using a central composite design. Breads were baked in a stone oven (1 m² internal baking surface). Response variables measured were specific volume, crumb porosity, crust to crumb ratio, crumb hardness, median gas cell size, crust coloration and acrylamide concentration. The specific volume, crumb porosity, crumb hardness and median gas cell diameter were mainly affected by the stone temperature and steam injection level. Highest specific volume (5 mL.g-1) and crumb porosity (86%) were obtained at highest stone temperature (230°C) and steam level (300 mL). At the same baking conditions and highest vault temperature (230°C), a minimal crumb hardness and median gas cell diameter were attained, as well. A negative linear correlation between the specific volume (crumb porosity) of the bread and its textural properties (crumb hardness and median gas cell diameter) was found. Vault temperature mainly influenced crust characteristics. Thus, increased vault temperature increased the crust coloration and crust crumb ratio. Vault temperature and steaming were found to have greatest effect on acrylamide concentration. As they were increased the acrylamide concentration increased, too. Additionally, a strong correlation between crust color and acrylamide concentration was observed. As the crust total color difference increased up to 20-25, acrylamide concentration increased linearly. However, for a higher level of crust coloration the acrylamide concentration was found to leveling out or even to decrease slowly.

Keywords

Baking, Heat and Mass Transfer, Acrylamide

Baking articles; Heat and Mass Transfer articles; Acrylamide articles

Baking articles Baking Research articles Baking review articles Baking PubMed articles Baking PubMed Central articles Baking 2023 articles Baking 2024 articles Baking Scopus articles Baking impact factor journals Baking Scopus journals Baking PubMed journals Baking medical journals Baking free journals Baking best journals Baking top journals Baking free medical journals Baking famous journals Baking Google Scholar indexed journals Heat and Mass Transfer articles Heat and Mass Transfer Research articles Heat and Mass Transfer review articles Heat and Mass Transfer PubMed articles Heat and Mass Transfer PubMed Central articles Heat and Mass Transfer 2023 articles Heat and Mass Transfer 2024 articles Heat and Mass Transfer Scopus articles Heat and Mass Transfer impact factor journals Heat and Mass Transfer Scopus journals Heat and Mass Transfer PubMed journals Heat and Mass Transfer medical journals Heat and Mass Transfer free journals Heat and Mass Transfer best journals Heat and Mass Transfer top journals Heat and Mass Transfer free medical journals Heat and Mass Transfer famous journals Heat and Mass Transfer Google Scholar indexed journals Acrylamide articles Acrylamide Research articles Acrylamide review articles Acrylamide PubMed articles Acrylamide PubMed Central articles Acrylamide 2023 articles Acrylamide 2024 articles Acrylamide Scopus articles Acrylamide impact factor journals Acrylamide Scopus journals Acrylamide PubMed journals Acrylamide medical journals Acrylamide free journals Acrylamide best journals Acrylamide top journals Acrylamide free medical journals Acrylamide famous journals Acrylamide Google Scholar indexed journals crumb porosity articles crumb porosity Research articles crumb porosity review articles crumb porosity PubMed articles crumb porosity PubMed Central articles crumb porosity 2023 articles crumb porosity 2024 articles crumb porosity Scopus articles crumb porosity impact factor journals crumb porosity Scopus journals crumb porosity PubMed journals crumb porosity medical journals crumb porosity free journals crumb porosity best journals crumb porosity top journals crumb porosity free medical journals crumb porosity famous journals crumb porosity Google Scholar indexed journals bread articles bread Research articles bread review articles bread PubMed articles bread PubMed Central articles bread 2023 articles bread 2024 articles bread Scopus articles bread impact factor journals bread Scopus journals bread PubMed journals bread medical journals bread free journals bread best journals bread top journals bread free medical journals bread famous journals bread Google Scholar indexed journals baking conditions articles baking conditions Research articles baking conditions review articles baking conditions PubMed articles baking conditions PubMed Central articles baking conditions 2023 articles baking conditions 2024 articles baking conditions Scopus articles baking conditions impact factor journals baking conditions Scopus journals baking conditions PubMed journals baking conditions medical journals baking conditions free journals baking conditions best journals baking conditions top journals baking conditions free medical journals baking conditions famous journals baking conditions Google Scholar indexed journals baking surface articles baking surface Research articles baking surface review articles baking surface PubMed articles baking surface PubMed Central articles baking surface 2023 articles baking surface 2024 articles baking surface Scopus articles baking surface impact factor journals baking surface Scopus journals baking surface PubMed journals baking surface medical journals baking surface free journals baking surface best journals baking surface top journals baking surface free medical journals baking surface famous journals baking surface Google Scholar indexed journals

Article Details

1. Introduction

The development of food production processes is facilitated by studying the interaction between process design, operational conditions and product characteristics. In bread making, baking is a key step in which the raw dough piece is transformed into a light, porous, readily digestible and flavorful product, under the influence of heat. The baking technology could be regarded as engineering of food structures through formation of correct dough to trap leavening gases and the fixing of these structures by the application of heat [1]. Baking is a complex process that involves heat and mass transfer, physical, chemical and biochemical changes in a product such as volume expansion, evaporation of water, formation of a porous structure, denaturation of protein, gelatinization of starch, crust formation and browning reaction [2]. Mathematically, it can be described as a simultaneous heat and water transport within the product, and with the environment inside the baking chamber [2-4]. Heat and water transport to the product occurs mainly through natural and forced convection, radiation, conduction from the mold, evaporation of water and condensing steam. Depending upon the product characteristics and oven type, relative contribution of the various mechanisms of heat transfer can be adjusted to achieve a desired quality in the final product. Due to the high energy consumption of the baking process, optimization of oven operating conditions is required to reduce energy consumption as well to improve product quality [2, 5]. Optimization of baking process requires an understanding of the physico-chemical changes involved in the process.

During baking, heat is transferred mainly by convection from the heating media and by radiation from oven walls to the product surface followed by conduction to the geometric center. At the same time moisture diffuses outward to the product surface. The temperature and moisture distribution within the product can be predicted using heat and water diffusion equations [2, 6]. The vital influence of final product quality includes the rate and amount of heat application, the humidity level in the baking chamber and baking time [2, 7]. The temperature and air humidity in the baking chamber have a major effect on the rate of heat transfer [8]. It is not always beneficial or desirable to have a maximum rate of heat transfer. However, it is always beneficial to be able to control the rate of heat transfer as this means the process can be controlled and made repeatable. Altering the heating rate during baking would potentially vary the kinetics, and extent of disordering of the amylopectin crystals, granule swelling, amylose leaching and, therefore, the effective crumb structure established within the product. These changes would subsequently impact the textural changes occurring in product during storage [9].

Temperature is the fundamental and most obvious factor that affects all three methods of heat transfer (convection, conduction, radiation). It is also the dominating factor in various physical, chemical and biochemical changes during baking: volume expansion, crust formation, inactivation of yeast and enzymatic activities, protein coagulation and gelatinization of starch in dough [7]. Humidity affects the heat transfer rate by allowing water vapor to condense on an object. When water condenses, heat is transferred to the object, and this is known as latent heat of condensation. This energy is comparable to the heat needed to turn the water into steam to start with. When a product is heated directly in a dry environment, it will experience higher temperatures to achieve the same heat transfer as a humid environment using latent heat effects. The level of humidity in the air also affects heat transfer in another specific way. The higher the humidity, the higher the specific heat capacity of a set volume of air (higher capacity to hold more energy). By control of the heat transfer rate and humidity level in the baking chamber, the following benefits could be achieved: products can be heated more effectively, and baking time could be reduced, because the desired core temperature is reached quicker; products can be heated more efficiently, and production costs can be reduced; products can be heated more appropriately, and the yield can be increased; the consistency and repeatability of products could be increased; humidity affects the product performance during baking and ultimately its quality (crust thickness, coloration and crumb formation).

Baking involves temperature, moisture content and volume changes that are strongly coupled [10]. Lots of modeling has been developed on baking considering individual phenomena taking place during baking [8]. A dramatic change of physical and chemical property of dough takes place during baking. A qualitative description of mechanical properties such as stress, strain and modulus of elasticity of bread is given by [11]. Zanoni et al. [12] developed the kinetic models for starch gelatinization and surface browning of bread during baking. Quadratic model to describe the effect of baking temperature and time on the bread quality attributes including crust color, crumb temperature and weight loss is developed by [13].

The air humidity in the oven during baking is known to have a big impact on the oven rise (expansion of the fermented dough at the beginning of baking); however, very studies have documented the impact of the amount of injected steam on the bread and on the crust structure. Two remarkable investigation have been carried out by Le-Bail et al. [14] and by Altamirano-Fortoul et al. [15]. In the first study, it was shown that the higher amount of injected steam yielded a higher specific volume and a lower crust crumb ratio; this was explained by the fact that the condensation of moisture (higher amount with higher steaming level) resulted in a delayed fixation of the outer surface of the loaf by drying effect. In turn the loaf had more opportunity to expand and less compression of the crust area by the internal expanding crumb was occurring. It was also observed that a higher steam level yielded a delayed heating (slower heating rate for the center of the bread at the beginning of baking) due to the fact that, even if the condensation is expected to contribute to an enhanced heat flux, the condensed water has to be evaporated when the surface temperature of the dough passes the dew point temperature. In addition, Altamirano-Fortoul et al. [15] showed that a higher amount of injected steam resulted in a higher specific volume, but also to a thicker skin of the crust, showing more disrupted and gelatinized starch granules (shown by SEM). The same author also observed that a higher amount of steam resulted in a darker and more glossy crumb, showing a lower moisture permeability level with higher steaming level.

Paloheimo et al. [16] studied the effect of baking temperature, baking level, humidity after steaming, air velocity and heat conduction from the hearth on the baking of bread. They developed regression models from the experimental data obtained for baking time (based on surface color and crumb temperature), baking loss, specific volume, color and theoretical energy consumption. Sommier et al. [17] studied the impact of the baking conditions (vault and hearth temperatures, water vapor injection) on bread macroscopic changes (dough expansion, scars opening, crust formation) in term of French bread baking. They reported that water vapor favors expansion, while vault and hearth temperatures mainly influence crust, the setting of which stops loaf volume decrease. The main trends fall in agreement with general results from literature, but specificity of French bread (limited value of expansion, crust thickness) were underlined. Chul Soo Park and Byung Kee-Baik [18] studied the influence of baking time and temperature on the quality characteristics of par-baked French bread (volume, weight, crust color, crumb firmness and moisture content). They reported that low temperature and long baking time tend to decrease the crumb firmness of the final bread. Starch gelatinization enthalpies of the bread crumb were similar in breads baked at different initial baking temperatures.

Acrylamide in food is mainly formed by a reaction between asparagines and reducing sugars [19-23]. Because acrylamide is classified as a probable carcinogen by the International Agency for Research on Cancer (IRAC, 1994), several strategies for reducing acrylamide have been proposed and are under investigation [24-31]. Besides formulation, the effects of various process parameters, heat regulation and final moisture content are crucial for the formation of acrylamide [32]. An optimized baking process is an appropriate tool for acrylamide reduction [19]. Most of the studies are focused on formulation and product composition, and only few of them have been designed to study systematically the effect of heat and mass transfer and baking conditions on acrylamide formation. The impact of the temperature-time baking regimes was examined in several studies [33-42].

Surdyk et al. [38] and Taeymans et al. [39] reported a decrease in acrylamide for bread baked at lower temperature for a longer time. Haase et al. [43] discussed the formation of acrylamide in baked products, and identified flour milling intensity and baking temperature as important factors affecting acrylamide concentration in bread. Their study showed reduced acrylamide content in rye bread, baked at lower temperatures and prolonged heating time, whereas Amrein et al. [40] reported an increase in acrylamide when such regimes were applied during gingerbread baking. Additionally, Claus et al. [33], Surdyk et al. [38] reported that acrylamide in wheat bread increased linearly with time and temperature. Bråthen and Knutsen [35] examined the effect of time and temperature on the formation of acrylamide in bread, flat bread, dry starch systems, and dried rye-based flat bread. In their study the amount of acrylamide was reduced at long baking times, except in the case of bread crust, where the amount of acrylamide increased with both baking time and temperature in the interval tested (180-280°C for 15-45 min). Mustafa et al. [36] studied the effect of baking time and temperature on acrylamide content and color of yeast - leavened whole - grain rye crisp bread. They reported that the combination of a long baking time and high baking temperature significantly increased acrylamide content. They found a correlation between acrylamide content and color of the milled bread, unless precursors were added.

Springer et al. [42] developed a special temperature profile with slightly increased oven inlet temperature and lower temperatures at the oven outlet for acrylamide reduction in crisp bread. They reported a significant reduction in the acrylamide content by changing the temperature/moisture profile during the baking process. A similar approach was proposed by Vass et al. [44] for the production of crackers. However, this implies longer baking times and, consequently, reduced line efficiencies [32]. The concept of falling baking temperature and the effect of steaming on acrylamide formation were studied by Ahrne et al. [34]. They reported that crust temperature in combination with water content has a significant effect on acrylamide formation and thus higher temperatures resulting in higher acrylamide concentration. At very high temperatures and lower water contents, acrylamide concentration is observed to decrease, though the bread colour is then unacceptable for consumption. Steam and falling temperature baking, decreased the acrylamide content while producing bread crust with an acceptable colour. The lowest acrylamide content and an acceptable crust color were produced by steam baking.

In addition to temperature, the rate of heat transfer from the oven to the product surface and oven type are also crucial for the acrylamide formation. Claus et al. [33] studied the differences between deck and convection ovens using wheat bread. In this study, a significant impact of the oven type on the acrylamide content of bread was observed. Higher acrylamide levels in breads baked in a convection oven, compared to deck ovens were observed, most probably due to the forced air circulation, leading to faster and more intense drying of the bread crust.

Additionally, Matthaus et al. [45] demonstrated that preparation of French fries in a convection oven resulted in slightly higher acrylamide levels than baking at top- and bottom-heat. In spite of the popularity of bread baking, the impact of the temperature-time regime, and oven type on acrylamide formation is still discussed controversially [33]. The present research aimed to determine the effect (investigate and model the impact) of the basic baking process parameters (temperature and steaming) on the physical and structural properties of bread (specific volume, porosity, crust crumb ratio, crumb hardness, median gas cell size and crust coloration) and acrylamide concentration.

2. Methods

2.1 Raw Materials

White flour supplied by Moulins Soufflet Pantin - Pornic, France and used for the formulation had the following basic properties: 0.53 Ash content, 10.58% protein on dry matter, falling number 402 s, Zeleny 38, alveograph parameters W = 183, P/L = 0.62, asparagine (libre)<0.02%. The composition of the dough was on a flour weight basis - for 100 g flour: 58 g water, 5 g compressed fresh yeast (Michard SAS - Theix, France), 2 g salt (Esco, Levallois Perret, France S.A.) and 1 g improver (PURATOS - Groot Bijgaarden - Belgium).

2.2 Bread-Making Procedure

Ingredients were mixed in a SP10 spiral mixer (VMI, Montaigu, France) during 2 min at 100 rpm and 7 min at 200 rpm. At the end of the mixing, dough temperature was found to be around 20°C. Dough was then rested for 15 min, and divided and molded in a divider - molder (Bongard, Holtzheim, France) to obtain dough pieces of 70 g each. The dough pieces were installed on aluminum trays (mass 670 g, size 40 cm × 80 cm). Up to 12 breads were installed on each tray. Dough pieces were pierced with 5 holes (needle piercing) and were placed in a fermentation cabinet (Panimatic, Souppes s/ Loing, France) for 60 min at 35°C, 95% relative humidity. A dough expansion ratio of 4 times the initial volume was observed at the end of fermentation.

Baking was performed in a batch electrical deck oven (MIWE CO 1.1208 - Germany) equipped with a stone hearth. The volume of the baking chamber is 0.3 m3 and the hearth surface is 1.02 m² (0.85 × 1.2 m). The baking sets were done at different vault/hearth temperatures and steam injection in accordance with the experimental design matrix under natural convection. The steam injection was applied immediately after the start of baking. For the whole set of experiments the chimney was opened 4 min after the start of baking. The specific occupation ratio in the oven was adjusted and kept around 1.65 kg dough/m2 (2 trays × 12 breads each). The end point of baking (or baking time) was considered as the time for which the temperature reached 98°C at the center of the bread, followed by another fixed period of 20 min. Such a condition corresponded to a prolonged baking. This definition for end point of baking was applied for the whole set of experiments. Temperature in the bread was logged with K type thermocouples (Omega, USA, 0.3 mm diameter) connected to a SA 32 Data Logger (AOIP-France). After baking, the breads were cooled for 1 hour at ambient temperature (20°C), before being analyzed.

2.3 Analysis of bread characteristics

2.3.1 Bread volume: A computer-controlled bread volume measuring instrument (BVM-L500, TexVol Instruments - Sweden), which employs laser sensor was used. At least 8 samples of each experimental set were measured. A calibration procedure was performed prior each test.

2.3.2 Crumb porosity: Porosity is a measure of the void spaces in a material, and is measured as a fraction, mostly as a percentage between 0-100%. The porosity is defined as  , where rbulk is the total density of the crumb (including gas alveolus), and rsolid is the density of the solid crumb. A helium pycnometer Accupyc 1330 (Micromerities-France) was used. It allows determining the actual density of a sample without taking into account the volume occupied by internal or open porosity. The actual density rsolid of the bread crumb was determined by cutting rectangular parallelepipeds of the crumb and by weighting them (tripilicate).

, where rbulk is the total density of the crumb (including gas alveolus), and rsolid is the density of the solid crumb. A helium pycnometer Accupyc 1330 (Micromerities-France) was used. It allows determining the actual density of a sample without taking into account the volume occupied by internal or open porosity. The actual density rsolid of the bread crumb was determined by cutting rectangular parallelepipeds of the crumb and by weighting them (tripilicate).

2.3.3 Crust/crumb ratio: Crust/crumb ratio was calculated as weight of crust referred to weight of crumb on dry basis [46]. Crust to crumb ratio was determined by separating the crust from loaf using razor blade; the criteria of separation was based on the dry and denser layer on surface of the bread that has a brownish to white color. Then they were placed in aluminum dishes and putted in drying oven at 103°C for 16 h (three replicates). Three loaves of bread sample were used for each analysis. The samples were cooled in a desiccator and weighed by an analytical balance with the sensitivity of ± 0.01 g.

2.3.4 Crumb hardness: Crumb hardness was measured at 1 hour after baking by the JJ Lloyd LR5K Texture Analyzer (Lloyd Instruments Ltd., UK). Twelve 15 mm thick slices were used for each compression test. The slices were taken from the middle of each bread sample. The crust of the slices was removed so that only textural parameters from the crumb were measured. The samples were compressed using a 20 mm diameter cylindrical probe moving at 20 mm/min. A constant degree of deformation was applied (40% of total height). The displacement was logged when the force was higher than 0.1 N. A load cell of 50 N was fixed on the moving head of the instrument. The maximum force (N) was extracted from the force-deformation curve.

2.3.5 Gas cell size: The distribution of the gas cells in the bread crumb was assessed using a procedure issued from mathematical morphology proposed to characterize visual texture in relation to particle size - Image Analysis [47]. Scanning was performed on color flatbed scanner “HP Scanjet G4010”. Scans of breads were analyzed by the image analysis software - Image J (Wright, Toronto, Canada). One hour after baking, breads were cut with electric slicer (Master 182 slicer -Graef, Arnsberg, Germany) transversely in order to obtain slices about 1.5 cm thick. Few slices were obtained per each bread, but just the middle ones were used for analysis. Special attention was paid to avoid cells damaging during this procedure.

The obtained digital image is divided into pixels (1378 × 1378 pixels) which individuals take a value between 0 (black) and 255 (white) - 8 bits grey level. The transformations are applied to the image through a structuring element - a square with size of (2n+1) pixels with a reference pixel at the center, n being the size (step) of the transformation. Erosion and dilation techniques consist in moving the structuring element through all image pixels. By applying structuring element at every step, images are continuously modified and information concerning the size of the objects can be obtained. In the case of erosion, the reference pixel is given the minimum value met by the structuring element. The effect is to decrease the size of clear objects larger than the size of the square considered and to remove those objects for which at least one dimension is less than (2n+1). In case of dilation, the reference pixel is given the maximum value met by the structuring element ((2n+1)2 square) - in result the size of dark objects is decreased and the objects smaller than the size of structuring element are removed. A granulometric characterization of texture is obtained by the so-called ¨closing¨ operation that consists in a step of dilation immediately followed by an erosion step of the same size [48, 49]. Twenty-five dilation and erosion steps were applied on the initial equalized image. The effect is to remove those dark objects (gas cells) smaller than the structuring element and to preserve the general size of larger ones. Increases of image volume measure the proportion of dark objects (gas cells) which have disappeared. The application of closings steps of increasing size acts as an image sieving of dark objects. The evolution of the image volume is normalized according to the initial volume. Variation of the sum of grey level for a given bread sample was less than 7%, indicating good stability and repeatability of the method.

Once the granulometric characterization is obtained the median gas cells diameter d50 is calculated by the cumulative curves. It corresponds to the diameter that includes 50% of the gas cells. Image processing program (plugin) was written in Image J software (U. S. National Institutes of Health, Bethesda, Maryland, USA) which is based on Java open code.

2.3.6 Surface color: Surface color of the bread samples was measured at three different positions on the bread surface using Sony DFW-SX910 (Japan) color digital camera equipped with FUJINON HF25HA-1B (China) lens. The CIE L*a*b (or CIELAB) color model was chosen to describe browning development. The CIELAB model is an international standard for color measurement developed by the Commission Internationale de l’Eclairage in 1976 [50]. The three parameters of the model represent the lightness (L*) and a* and b* the chromaticity co-ordinates. Triplicate readings were carried out per each experimental set, and the mean value was recorded. The response was expressed as the total color difference , as follows:

where, L*, a*, b* are the values of the sample, and L0, a0, b0 - values of the reference (unbaked dough- start of baking).

Conversion between color spaces (RGB to XYZ, and XYZ to CIE L*a*b*) was done using an algorithm developed on Matlab 6.5 (The MathWorks, Inc., Natick, MA, USA).

2.3.7 Measurement of acrylamide: Acrylamide native electropheresis grade 99%, potassium hexacyanoferrate, zinc sulfate heptahydrate, potassium ferrocyamide II Pd and zinc acetate were purchased from Acros (Geel, Belgium). A powder of 13C3-acrylamide was purchased from Euriso-top (Saint Aubin, France). Methanol GPR Rectapur was purchased from VWR Merck (Darmstadt, Germany). Microspin 0.45 µm PVDF centrifuge filter was purchased from Grace (Deerfield, IL, USA). Carrez I solution was prepared by dissolving 15 g of potassium hexacyanoferrate in 100 ml of water, and Carrez II solution by dissolving 30 g of zinc sulfate in 100 ml of water. After baking the whole crust layer was carefully separated from the bread; the distinction between the crust and the crumb was based on a physical separation between the dry outer layer of the bread and the moist crumb located inside the bread. The crumb was removed from the crust by scratching gently the crumb until obtaining the cry outer crust material. The crust that was obtained was dried at 30°C in a drying cabinet with air circulation over night. After that, the dried crusts are finely grounded and stored at -21°C.

Two grams of each ground sample along with 0.2 ml of dilute stock solution of isotopic standard and 20 ml of methanol is thoroughly homogenized and then one ml of each Carrez is added. Two aliquots of the top layer of the extract is transferred to two Micro spin tubes and centrifuged for 10 minutes at 10,000 rpm. The clear solution is filtered through a 0.45 micro filter into a brown vial and stored at -5 to +5°C. The acrylamide extract (1 µL) was injected onto a gas chromatograph (GC) Agilent 5890 series II coupled to an mass selective detector Agilent 5972 series, quadrupole mass spectrometer (MS) (Agilent Technologies, Palo Alto, CA) in splitless mode at 150°C. Helium carrier gas flow rate was maintained at 1ml/min. An HP INNOWAX polar capillary column was used (30 m × 250 µm id, 0.25 µm film thickness, J&W Scientific, Folsom, USA). The oven temperature was 80°C (0 min of isothermal), rising at 10°C/min to 250°C and followed by holding for 13 min. The transfer line was held at 250°C and the ion source at 180°C. Electron impact mass spectra were obtained at 70eV. The mass spectrometer was operated in selected ion monitoring mode (SIM). Two ions were used to characterize 13C3-acrylamide (m/z 58 and 74) and two ions were used to characterize acrylamide (m/z 55 and 71). The ion m/z 71 was used to quantify acrylamide.

2.4 Experimental design

The independent variables in this study were vault temperature (X1), hearth temperature (X2) and steam injection (X3). The effects of these variables were analyzed on the following responses: bread specific volume Vs; crumb porosity e; median gas cell diameter d50, crumb hardness F, crust/crumb ratio c/c, crust total color difference and acrylamide concentration in the crust Ac. The total baking time for the all experimental sets was tb, where tb is the time for which the crumb center reaches 98°C. The experiment was designed by an orthogonal central composite design (CCD).

Central Composite design having 16 experimental runs with different combination of factors was conducted using Statgraphics plus 5.0 (Statistical Graphic Corp., USA) in order to study the main effects and their interactions. Effects were considered significant when the level of probability p<0.05. Three repetitions of the centre point were done in order to estimate the experimental error. Model performance was evaluated by calculating the lack of fit sum of squares (F-test), the correlation coefficient (R2) and graphical residual analysis. The model was considered adequate at lack of fit sum of squares probability more than 0.05 and R2 more than 0.8. The axial distance of the star (a), was chosen to be 1.28719. The actual values and the corresponding coded values of the independent variables are given in Table 1. For statistical data analysis all experiments were done in triplicate, totaling 48 experiments.

|

Operating conditions |

Coded levels |

||||

|

-1.287 |

-1 |

0 |

1 |

1.287 |

|

|

Uncoded levels |

|||||

|

vault temperature - X1, (°C) |

161 |

170 |

200 |

230 |

239 |

|

hearth temperature - X2, (°C) |

161 |

170 |

200 |

230 |

239 |

|

steam injection - X3, (ml) |

71 |

100 |

200 |

300 |

329 |

Table 1: The coded and actual values of the levels of the independent factors.

3. Results and Discussion

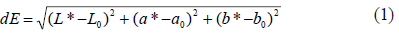

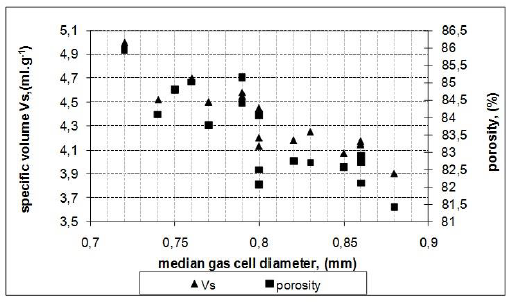

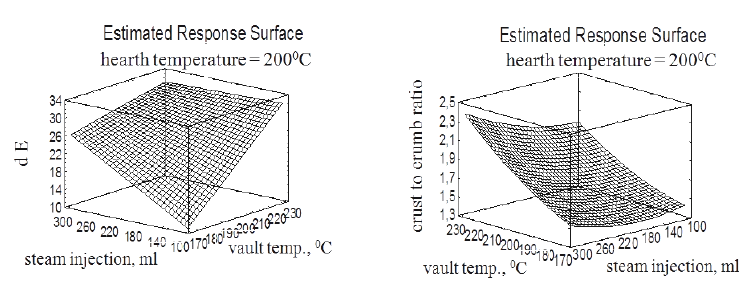

After screening, 48 experimental data with varied vault/hearth temperature and steam injection levels were used for modelling. The regression equations and coefficients were determined from the analysis of response surface design. For each of the response variables, model summaries and lack of fit tests were analysed for linear and quadratic models. From this information, the most accurate model was chosen, which in all cases was quadratic, just in the case of total colour difference it was linear. Three-dimensional response surface plots were generated for each quality parameter (Figure 1, Figure 2, Figure 5, Figure 7 and Figure 8). The achieved mathematical models, expressed in scaled variables are presented in Table 2. The effects of the baking conditions on the bread quality properties and acrylamide content are shown in Figure 1, Figure 2, Figure 5, Figure 7 and Figure 8. Analysis of the obtained models (Table 2) showed that hearth temperature and the combined effect of hearth temperature and steaming had the greatest effect (positive correlation) on crumb porosity (ε) and specific volume (Vs). Both porosity and specific volume increased with increasing hearth temperature and steaming (Figure 1). Highest specific volume and porosity are achieved at highest hearth temperature (230°C) and steaming level (300 ml). However, the significance of the quadratic effect of the vault temperature indicates that the specific volume and porosity go through a local minimum at around 200°C.

According to He and Hoseney [51], during baking the growth of the gas bubbles determines the expansion of the dough and therefore the ultimate volume and texture of the baked product. The limit of expansion is related to the rupture of the bubble walls caused by the loss in gas retention. Thus, the expansion depends on the dynamic equilibrium between internal pressure in the gas cells and viscous forces of the continuous phase. As temperatures rise, gases move to the air cells formed during mixing, enlarging them and the product increases in size and volume (oven spring). However, crust formation caused mainly by the vault temperature is a factor limiting the bread expansion during baking. Crust formation restricts the expansion of the closed gas cells in the dough resulted in increased internal pressure, additionally stressing the cell membranes. If they are not able to resist on the increased pressure, the cell membranes will rupture on very early stage of baking and the cells will coalesce, resulting in low loaf volume and coarse crumb structure. At the same time further increasing of the vault temperature, accelerates the moisture (mass) loss during baking, and thus the final specific volume of the bread, defined as a ratio of loaf volume to loaf mass, could increase because of the lightening of the loaf (Figure 1). Applying steam to the dough during the early stages of baking keeps the outer dough layer flexible and moist. The dough continues to rise for a longer period of time and the oven spring and loaf volume are higher. Steam allows the yeast to work a little longer in the dough and this, combined with a hot baking surface, produces an extra push of volume. Once, the outside layer of the dough sets, gases in the loaf can no longer expand to increase the loaf size. Thus, steam promotes higher oven rise and also prevents wild breaks in the loaves because it delays the setting of the bread’s crust, allowing it more time to bake and brown. In addition, it is well known, that crust is not a thermal insulation layer rather it acts like a barrier towards weight loss during baking [52]. As steaming delays crust formation, the weight loss is higher and therefore the final mass of the bread is reduced, resulting in higher specific volume.

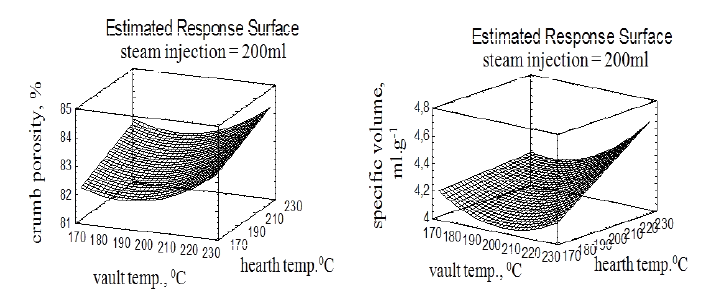

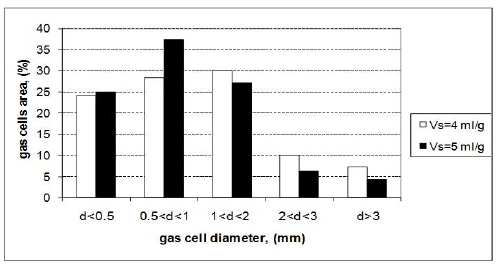

Hearth temperature and quadratic effect on the vault temperature had the greatest influence on median gas cell diameter (d50). Increasing the hearth temperature tends to decrease the median gas cell diameter. The significance of the vault temperature quadratic effect shows that the median diameter goes through a local maximum centred at around 200°C (Figure 2). At the highest and lowest hearth and vault temperatures tested (170°C and 230°C) the median gas cell diameter was smallest. These results correlate very well with the specific volume and crumb porosity (Figure 3). It seems that higher specific volume and porosity are obtained at smaller median gas cell diameter. The same tendency is observed in Figure 4, which represents the gas cell size distribution for different specific volumes. The distributions appear to be unimodal. Analysis of the results (Figure 4) indicate that in the case of higher specific volume (Vs=5 mL.g-1) about 63% of the gas cells in the bread have diameter lower than 1mm, while for Vs=4 mL.g-1 they are just 50%. Higher porosity and specific volume are caused by the increased population (number) of smaller and more uniform gas cells per unit volume, as their specific surface area per unite volume is higher.

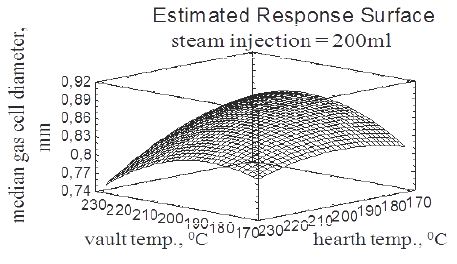

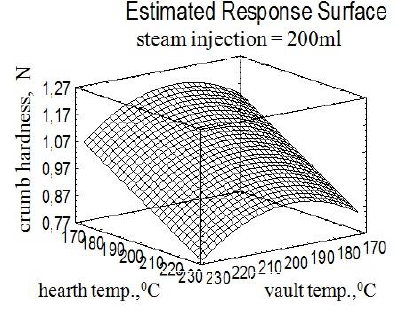

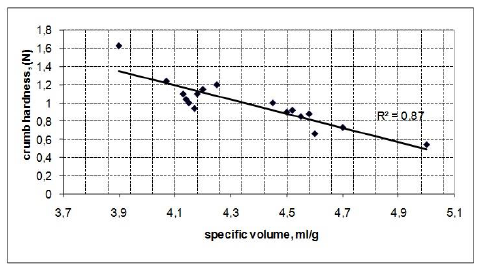

The most significant variables affecting the crumb hardness were the hearth temperature and the combined effect of hearth temperature and steaming. The crumb hardness decreased as the hearth temperature and the combined effect were increased. The softest crumb (lowest hardness) was attained at the highest hearth temperature (Figure 5). The obtained data for the crumb hardness correlate very well with those for the specific volume and porosity of the bread (Figure 6). As higher is the specific volume (porosity) as lower is the crumb hardness. This could be explained by the thinner cell walls, caused by the higher expansion ratio of the dough baked at higher temperature and steaming levels, and by the more uniform gas cell size distribution for a higher specific volume (Figure 4). Crumb heterogeneity caused by a presence of large cells has a physical significance on crumb mechanical properties as introduces regions where stress concentrations can arise [53]. On the three baking parameters, vault temperature had the greatest effect (positive correlation) on bread coloration (dE) and crust to crumb ratio (c/c) (Table 2). As soon as the dough is placed in the oven, water evaporates very fast from the surface layers, resulting in much lower water content than at the core. As the water content decreases in the crust, the temperature can exceed 100°C and tends to the oven temperature, which supports reactions such a caramelization, carbonization and Maillard reaction, responsible for the crust coloration. These reactions belong to the non enzymatic or non oxidative browning category. The Maillard reaction is the main responsible for color development at temperatures below 150°C. Caramelization and carbonization reactions take place at temperatures above 150°C. The Maillard reaction is influenced by composition in reducing sugar and amino acids, but also by temperature, pH, moisture content [12].

Thus the crust and color development depend strongly on the temperature - the higher is the surface temperature the higher is the moisture loss of the surface layers (crust formation) and the Maillard reaction between sugar and amino acids, which gives more melanoids during baking is accelerated, resulting in darker color of the surface [54]. Surface temperatures exceeding 100°C could be explained by the difference in water content between surface and core - water evaporates from the surface more quickly than it can be transported from the core [55]. Evaporation of water regulates the dough temperature so that, under normal baking conditions, no part of the dough mass reaches a temperature significantly above the boiling point until its water content is so low that evaporation is restricted and the balance between heat absorption and evaporation loss is altered. Beyond this stage, formation of crust commences.

Water vapor was injected at the start of baking. The addition of steam increases the relative humidity of the oven air, dramatically. As long as the surface temperature of the dough is below the dew point, the moisture contained in the air condenses onto it, resulting in the release of the latent heat of condensation (absorbed by the dough) and in an enhanced heat transfer at the dough surface. Thus, the increased steam injection level during the first minutes of baking, favors crust browning (Figure 7). Similar trends are reported in the literature by [56] which explained this by an enhanced heat transfer from the oven atmosphere to the dough and by [15], which explained this by the fact that starch exposed to high moisture condensation at the surface of the bread undergoes gelatinization, which contributes to the release of reducing sugars and in turned a higher level of Maillard reaction.

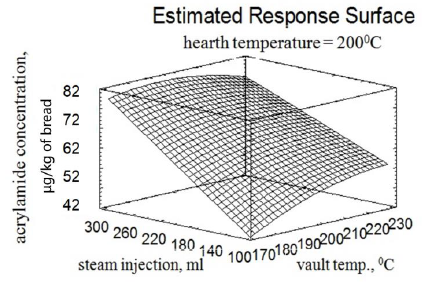

The Maillard reaction is important for the formation of aroma and color in the bread crust, but may also be associated with the formation of toxic compounds, such as acrylamide [21, 22, 57]. The greatest effect (positive correlation) on the acrylamide concentration (Ac) had the steam injection and vault temperature (Table 2). The acrylamide concentration varied between 40-77 µg/kg of bread. In comparison, these values are lower than those reported previously in the literature. Acrylamide concentration in bread crust is reported to range between 85 and 230 µg/kg of crust for conventional baking at 200-270°C for 10-20 min [34, 38]. This difference can be explained by different point of view. At first, a less pronounced level of baking was used in this project. Another point is that in these papers, the acrylamide concentration is given per mass of crust but not per mass of bread and there is no precise definition and objective criteria about how crust is differentiated by crumb. That might therefore greatly affect the final measured acrylamide concentration even though the determination of the acrylamide per kg of bread should yield lower values. The concentration based on the mass of bread is more representative than based on the mass of crust due to the lack of precision to separate the crust and the crumb. It should be put to the fore that the concentration of acrylamide per mass of product is considered in the ongoing European regulation and in all regulatory documentation. As a consequence, any direct comparison with the studies of Ahrne et al. [34], Surdyk et al. [38] is impossible.

Based on our results, we found out that the amount of acrylamide in the crust increased with the steam level and vault temperature (Figure 8). The lowest concentration of acrylamide was found in the case of lowest steam and vault temperature levels. Increased steam injection and vault temperature levels tend to increase the acrylamide concentration. However, a slight decrease of the acrylamide was observed, when the vault temperature is above 200°C and the steaming is high (300 mL) (Figure 8). Similar trends are reported by [20, 58].

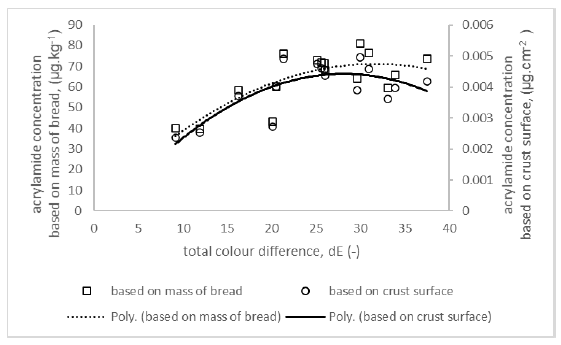

A strong correlation between crust colour and acrylamide concentration had been reported by Surdyk et al. [38]. Similarly, our results indicate a strong positive correlation between acrylamide concentration and total colour difference dE (Figure 9). They are linearly correlated up to a colour value of dE=20¸25, after which acrylamide content tends to levelling off and even to decreases slightly with the crust coloration. A similar tendency of reversing is reported by Ahrne et al. [34]. However, our results regarding the impact of the steam injection on acrylamide formation are not in agreement with those of Ahrne et al. [34], who reported that steam baking decreases acrylamide concentration. This contradiction could be explained in term of the time when the steam is injected into the oven. Ahrne et al. [34] injected the steam into the oven in the 5th, 10th and 15th min and retained in it until the end of baking. In such conditions, the steaming yielded a lower moisture loss from the crust, contributed to reduce the crust temperature and therefore the temperature difference between outer and inner crust, resulting in a lower acrylamide concentration. In our case the steam was injected immediately after the dough was placed in the oven, causing condensation of the vapour on the cold dough surface, release of the latent heat of condensation slowing down at first the heat up rate of the dough [14], partial to complete gelatinization of starch accompanied by a chance of release of reducing sugars, and once the condensed vapour was vaporized enhanced heat transfer resulting finally in a darker crust. In addition, the chimney in our study was opened 4 minutes after the start of baking, which facilitated extraction of the moisture contained in the oven cavity resulting in a substantial drying of the crust layer, which favours acrylamide formation.

Figure 9 represents the dependency between dE and acrylamide concentration given in two different units - µg.kg-1 (per mass of bread) and µg.cm-2 (per crust surface area). The area of the bread was determined from the ratio or mass per specific volume; since all breads were made from the same mass of dough, there was no artefact. Nevertheless, that the majority of the published results in the literature have been reported as acrylamide per unit mass, crust surface area that takes into account bread volume as well would represent in a better way the acrylamide concentration in the crust layer as evident from the figure. Some regulation of food contaminants such as the regulation on PFOS and PFOA (contaminants for non-sticking coating) propose values in both mass of contaminant per mass of products and mass per surface of product [59].

|

Quality parameter |

Equation |

R2 |

lack of fit test (p-value) |

|

Vs |

Y1=4.1676+0.0832X1+0.1407X2+0.0068X3+0.151X12+0.115X1X2+ 0.2475X2X3+0.136X32 |

0.93 |

0.09 |

|

ε |

Y2=82.459+0.494X1+0.5142X2+0.0115X3+0.7599X12+1.1825X2X3+ 0.7176X32 |

0.87 |

0.66 |

|

d50 |

Y3=0.8608-0.0038X1-0.0275X2-0.0025X3-0.0378X12-0.0238X1X2-0.0197X22-0.0238X2X3-0.0258X32 |

0.93 |

0.16 |

|

F |

Y4=1.0977-0.05X1-0.1476X2-0.031X3-0.1434X12-0.1938X2X3 |

0.81 |

0.63 |

|

c/c |

Y5=1.7956+0.3646X1+0.1184X2+0.1191X3-0.125X1X2+0.0765X1X3 +0.1215X2X3+0.0769X32 |

0.97 |

0.09 |

|

dE |

Y6=25.091+6.699X1+3.4413X2+3.7742X3-4.0275X1X3+2.0975X2X3 |

0.98 |

0.1 |

|

Ac |

Y7=65.99+2.8 X1+14.16 X3-2.54 X12-4.38 X1X3 |

0.94 |

0.12 |

*Only values of significant coefficients are presented (p<0.05)

Table 2: Mathematical models.

Figure 1: Effects of vault (X1) and hearth temperature (X2) on crumb porosity (ε) and specific volume (Vs) for 200 ml of steam injection (X3).

Figure 2: Effect of vault (X1) and hearth temperature (X2) on median gas cell diameter (d50) for 200 ml of steam injection (X3).

Figure 3: Median gas cell diameter vs. specific volume and crumb porosity.

Figure 4: Gas cell size distribution obtained by image analysis of bread slices with different specific volume.

Figure 5: Effect of vault (X1) and hearth temperature (X2) on crumb hardness F (N) for 200 ml of steam injection (X3).

Figure 6: Crumb hardness vs. specific volume of bread.

Figure 7: Effect of vault (X1) temperature and steam injection (X3) on crust total colour difference (dE) and crust to crumb ratio (c/c) for hearth temperature = 200°C.

Figure 8: Effect of steam injection (X3) and vault temperature (X1) on acrylamide concentration (Ac) for hearth temperature = 200°C.

Figure 9: Total colour difference dE vs. acrylamide concentration Ac based on mass of bread and on crust surface area.

5. Conclusion

Mathematical models have been developed to describe the effect of the vault/hearth temperature and steam injection on the specific volume, crumb porosity, median gas cell size, crumb hardness, crust to crumb ratio, crust coloration and acrylamide concentration. Analysis of the obtained models showed that: maximal specific volume (5 ml.g-1) and porosity (86%) were attained for highest hearth temperature (230°C) and steam injection (300 ml). At the same baking conditions and highest vault temperature (230°C) the minimal crumb hardness and median gas cell diameter were attained as well. A negative linear correlation between the specific volume (crumb porosity) of the bread and its textural properties (crumb hardness and median gas cell diameter) was found. Of the three process parameters, vault temperature exhibited the greatest effects on crust coloration and crust to crumb ratio. As vault temperature increased, both crust coloration and crust to crumb ratio increased, too. Vault temperature and steaming were found to have greatest effect on acrylamide concentration. As they were increased the acrylamide concentration increased, too. Moreover, a correlation between crust color and acrylamide concentration was observed. As the crust total color difference increased up to 20-25, acrylamide concentration increased linearly. Beyond this value the acrylamide concentration was found to leveling out or even to decrease slowly.

Acknowledgements

This study has been carried out with financial support of the region Pays de Loire (Regional Project AISQAL) and with the financial support from the Commission of the European Communities, FP6, Thematic Area “Food quality and safety”, FOOD-2006-36302 EU-FRESH BAKE. It does not necessarily reflect its views and in no way anticipates the Commission’s future policy in this area. Tzvetelin DESSEV is a post doc co-funded by the region Pays de Loire and EU-FRESHBAKE. Thanks to, Sylvie CHEVALLIER, Luc GUIHARD and Christophe COUEDEL for the technical support.

References

- Balaji N. Modelling of transient temperature distribution during bread baking by finite difference analysis, in IIT: Kharagpur, India (1991).

- Sablani SS, Marcotte M, Baik OD, et al. Modeling of simultaneous heat and water transport in the baking process. Lebensm.-Wiss. U.-Technol 31 (1998): 201-209.

- Vanin FM, Grenier D, Doursat C, et al. Insights into water loss and crust formation during bread baking. II. Technological teachings from a sensitivity analysis. Journal of Food Engineering (2009).

- Vanin FM, Lucas T and Trystram G. Crust formation and its role during bread baking. Trends in Food Science and Technology 20 (2009): 333-343.

- Carvalho MG and Martins N. Mathematical modeling of heat and mass transfer in a forced convection baking oven. AIChE Symposium Series-Heat transfer. San Diego, CA, USA: AIChE (1993): 205-211.

- Thorvaldsson K and Janestad H. A model for simultaneous heat, water and vapor diffusion. Journal of Food Engineering 40 (1999): 167-172.

- Pyler EJ. Baking science & Technology. 1988, Meriam: Sosland Publishing Company (1988).

- Mondal A, Datta AK. Bread baking - A review. Journal of Food Engineering 86 (2008): 465-474.

- Patel BK, Waniska RD, Seetharaman K. Impact of different baking processes on bread firmness and starch properties in breadcrumb. Journal of Cereal Science 42 (2005): 173-184.

- Zhang J and Datta AK. Mathematical modeling of bread baking process. Journal of Food Engineering 75 (2006): 78-89.

- Scanlon MG and Zghal MC. Bread properties and crumb structure. Food Research International 34 (2001): 841-864.

- Zanoni B, Peri C, and Bruno D. Modelling of browning kinetics of bread crust during baking. Lebensmittel-Wissenschaft und-Technologie 28 (1995): 604-609.

- Therdthai N, Zhou W, Adamczak T. Optimisation of the temperature profile in bread baking. Journal of Food Engineering 55 (2002): 41-48.

- Le-Bail A, Dessev T, Leray D, et al. Influence of the amount of steaming during baking on the kinetic of heating and on selected quality attributes of bread. Journal of Food Engineering 105 (2011a): 379-385.

- Altamirano-Fortoul R, Le-Bail A, Chevallier S, et al. Effect of the amount of steam during baking on bread crust features and water diffusion. Journal of Food Engineering 108 (2012): 128-134.

- Paloheimo M, Malkki Y, Kaijaluoto S. Optimization of baking process: combined heat transfer, Thermal Processing and Quality of Foods. Elsevier Applied Science Pub: London (1984): 487-491.

- Sommier A, Chiron H, Colonna P, et al. An instrumented pilot scale oven for the study of French bread baking. Journal of Food Engineering 69 (2005): 97-106.

- Chul-Soo-Park and Byung-Kee-Baik. Influence of baking and thawing conditions on quality of par-baked French bread. Cereal Chemistry 84 (2007): 38-43.

- Claus A, Carle R, Schieber A. Acrylamide in cereal products: A review. Journal of cereal science 47 (2008): 118-133.

- Becalski A, Lau BPY, Lewis D, et al. Acrylamide in foods: occurrence, sources, and modeling. Journal of Agricultural and Food Chemistry 51 (2003): 802-808.

- Mottram DS, Wedzicha BL, Dodson AT. Acrylamide is formed in the Mailard reaction. Nature 419 (2002): 448-449.

- Stadler RH, Blank I, Varga N, et al. Acrylamide from Maillard reaction products. Nature 419 (2002): 449-450.

- Weisshaar R and Gutsche B. Formation of acrylamide in heated potato products - model experiments pointing to asparagines as precursor. Deutsche Lebensmittel-Rundschau 98 (2002): 397-400.

- Morales, Capuano E, Fogliano V. Mitigation strategies to reduce acrylamide formation in fried potato products. Annals of the New York Academy of Sciences 1126 (2008): 89-100.

- Friedman M, Levin CE. Review of methods for the reduction of dietary content and toxicity of acrylamide, Journal of agricultural and food chemistry 56 (2008): 6113-6140.

- Zhang Y, Chen J, Zhang X, et al. Addition of bamboo leaves effectively reduces acrylamide formation in potato crisps and French fries. Journal of agricultural and food chemistry 55 (2007): 523-528.

- Granda C, Moreira RG, Tichy SE. Reduction of acrylamide formation in potato chips by low temperature vacuum frying. Journal of food sciences 69 (2004): 405-411.

- Rydberg P, Eriksson S, Tareke E, et al. Investigations of factors that influence the acrylamide content of heated foodstuffs. Journal of Agricultural and Food Chemistry 51 (2003): 7012-7018.

- Jung MY, Choi DS, Ju JW. A novel technique for limitation of acrylamide formation in fried and baked corn chips and in French fries. Journal of Food Science 68 (2003): 1287-1290.

- Grob K, Biedermann M, Biedermann-Brem S, et al. French fries with less than 100 lg/kg acrylamide. A collaboration between cooks and analysts. European Food Research and Technology 217 (2003): 185-194.

- Tareke E, Rydberg P, Karlsson P, et al. Analysis of acrylamide, a carcinogen formed in heated foodstuffs. Journal of Agricultural and Food Chemistry 50 (2002): 4998-5006.

- Stadler RH. The formation of acrylamide in cereal products and coffee. In Eds.: Skog K, Alexander J. Acrylamide and Other Hazardous Compounds in Heat-treated Foods. Woodhead Publishing, Cambridge (2006): 23-40.

- Claus A, Mongili M,Weisz G, et al. Impact of formulation and technological factors on the acrylamide content of wheat bread and bread rolls. Journal of Cereal Science 47 (2008): 546-554.

- Ahrné L, Andersson CG, Floberg P, et al. Effect of crust temperature and water content on acrylamide formation during baking of white bread: Steam and falling temperature baking. LWT - Food Science and Technology 40 (2007): 1708-1715.

- Bråthen E and Knutsen SH. Effect of temperature and time on the formation of acrylamide in starch-based and cereal model systems, flat breads and bread. Food Chemistry 92 (2005): 693-700.

- Mustafa A, Andersson R, Rosen J, et al. Factors influencing acrylamide content and color in rye crisp bread. Journal of agricultural and food chemistry 53 (2005): 5985-5989.

- Elmore JS, Koutsidis G, Dodson AT, et al. Measurements of acrylamide and its precursors in potato, wheat, and rye model systems. Journal of Agricultural and Food Chemistry 53 (2005): 1286-1293.

- Surdyk N, Rosen J, Andersson R, et al. Effects of asparagines, fructose, and baking conditions on acrylamide content in yeast-leavened wheat bread. Journal of Agricultural and Food Chemistry 52 (2004): 2047-2051.

- Taeymans D, Wood J, Ashby P, et al. A review of acrylamide: an industry perspective on research, analysis, formation, and control. Critical Reviews in Food Science and Nutrition 44 (2004): 323-347.

- Amrein TM, Schonbachler B, Escher F, et al. Acrylamide in gingerbread: critical factors for formation and possible ways for reduction. Journal of Agricultural and Food Chemistry 52 (2004): 4282-4288.

- Biedermann M, Grob K. Model studies on acrylamide formation in potato, wheat flour and corn starch; ways to reduce acrylamide contents in bakery ware. Mitteilungen aus Lebensmitteluntersuchung und Hygiene 94 (2003): 406-422.

- Springer M, Fischer T, Lehrack A, et al. Acrylamidbildung in Backwaren. Getreide, Mehl und Brot 57 (2003): 274-278.

- Haase NU, Matthaus B, Vosmann K. Acrylamide formation in foodstuffs - minimizing strategies for potato crisps. Deutsche Lebensmittel-Rundschau 99 (2003): 87-90.

- Vass M, Amrein TM, Schonbachler B, et al. Ways to reduce acrylamide formation in cracker products. Czech Journal of Food Science 22 (2004): 19-21.

- Matthaus B, Vosmann K, Haase NU. Pommes Frites: Einflussmo glichkeiten auf den Acrylamidgehalt. Ernahrung im Fokus 3 (2003): 235-239.

- Barber S, Martínez Anaya MA, Benedito de Barber C, et al. Un modelo de evaluación de la calidad de panes típicos regionales. Revista de Agroquímica y Tecnología de Alimentos 27 (1987): 291-303.

- Bertrand D, Le-Guerneve C, Devaux MF, et al. Description of the textural appearance of bread crumb by video image analysis. Cereal Chemistry 69 (1992): 257-261.

- Devaux MF, Robert P, Melcion JP, et al. Practicle size analysis of bulk powders using mathematical morphology. Powder Technology 90 (1997): 141-147.

- Rouille J, Della-Valle G, Devaux MF, et al. French bread loaf volume variations and digital image analysis of crumb grain changes induced by the minor components of wheat flour. Cereal chemistry 82 (2005): 20.

- Yam KL and Papadakis SE. A simple digital imaging method for measuring and analyzing color of food surfaces. Journal of Food Engineering 61 (2004): 137-142.

- He H and Hoseney RC. Gas retention of different cereal flours. Cereal Chemistry 68 (1991): 334-336.

- Wahlby U and Skjoldebrand C. Reheating characteristics of crust formed on buns, and crust formation. Journal of Food Engineering 52 (2002): 177-184.

- Zghal MC, Scanlon M, and Sapirstein H. Cellular structure of bread crumb and its influence on mechanical properties. Journal of Cereal Science 36 (2002): 167-176.

- Hadiyanto A, Asselman G, van Straten RM, et al. Quality prediction of bakery products in the initial phase of process design. Innovative Food Science and Emerging Technologies 8 (2007): 285-298.

- Zhang L, Lucas T, Doursat C, et al. Effects of crust constraints on bread expansion and CO2 release. Journal of Food Engineering 80 (2007): 1302-1311.

- Eliasson AC and Larsson K. Cereals in breadmaking. A molecular colloidal approach. New York: Marcel Dekker Inc (1993).

- Zyzak DV, Sanders RA, Stojanovic M, et al. Acrylamide formation mechanism in heated foods. Journal of Agricultural and Food Chemistry 51 (2003): 4782-4787.

- Bagdonaite K and Murkovic M. Factors affecting the formation of acrylamide in coffee. Czech Journal of Food Sciences 22 (2004): 22-24.

- Le-Bail A, Lebizec B, Durand S, et al. Food contact material for baking a review on associated chemical risks and technological issues, EHEDG Yeabook 2011-2012 (2011b): 75-88.

- Demirekler P, Sumnu G, Sahin S. Optimization of bread baking in a halogen lamp-microwave combination oven by response surface methodology. European Food Research Technology 219 (2004): 341-347.

- Haase NU, Matthaus B, Vosmann K. Acrylamid in Backwarenein Sachstandbericht. Getreide, Mehl und Brot 57 (2003): 180-184.

- Myers RH and Montgomery DC. Response surface Methodology (RSM): Process and product optimization using designed experiments. Wiley-Interscience Publication, USA (2002): 1-3.

- Ozdemir M and Devres O. Analysis of color development during roasting of hazelnuts using response surface methodology. Journal of Food Engineering 45 (2000): 17-24.

- Sevimli KM, Sumnu G, Sahin S. Optimization of halogen lamp-microwave combination baking of cakes: a response surface methodology study. European Food Research and Technology 221 (2005): 61-68.