Development, Organoleptic Evaluation and Acceptability of Products Developed by Incorporating Foxtail Millet

Article Information

Zainab Fatima* and Avanti Rao

Department of Nutrition and Dietetics, Madina Degree and PG College for Women, Hyderabad, India

*Corresponding Author: Zainab Fatima, Department of Nutrition and Dietetics, Madina Degree and PG College for Women, Hyderabad, India

Received: 10 May 2019; Accepted: 22 May 2019; Published: 14 June 2019

Citation: Zainab Fatima and Avanti Rao. Development, Organoleptic Evaluation and Acceptability of Products Developed by Incorporating Foxtail Millet. Journal of Food Science and Nutrition Research 2 (2019): 128-135.

View / Download Pdf Share at FacebookAbstract

Millets have been neglected despite the nutritive value and therapeutic use. Foxtail millet is highly nutritious, non-glutinous and non-acid forming food. They are a rich source of protein, fiber and neutraceutical components. Hence, they are soothing and easy to digest. The aim of the present study was to incorporate foxtail millet into six different recipes namingly, laddu, peanut chutney, panjeri, kheer, cutlet and chakli. Among these chakli was excluded due to its less acceptability. Remaining five recipes laddu, panjeri, kheer, cutlet, peanut chutney were well accepted. The products were evaluated by numerical scoring by 38 semi-trained panelists to asses overall acceptability. While considering these products, the highest score for overall acceptability was 84.2 for variation 1 in case of laddu, then 83.4 for variation 1 in case of kheer, 83.4 for variation 2 in case of panjeri and 82.6 for variation 1 in case of peanut chutney. The most acceptable products, namely laddu, kheer, peanut chutney, panjeri were subjected to hedonic rating test with 51 semi-trained panelists. The result showed that in case of kheer, variation 2 was more acceptable with the score of (8.10 ± 0.92) followed by (7.96 ± 0.85) for variation 1. In case of laddu, variation 2 was more acceptable with the score of (8.75 ± 0.52) followed by (8.33 ± 0.65) for variation 1. In case of peanut chutney, variation 1 was more acceptable with the score of (8.10 ± 0.67) followed by (7.94 ± 0.95) for variation 2. In case of panjeri, variation 2 was more acceptable with the score of (8.37 ± 0.85) followed by (8.16 ± 0.83) for variation 1. Data was analyzed using ANOVA, which shows a significant difference between variation 1 and variation 2 of laddu and kheer at 1% and 5% level of significance and no significant difference was observed between variation 1 and variation 2 of peanut chutney and panjeri at 1% and 5% leve

Keywords

Foxtail millet, Laddu, Panjeri, Kheer, Peanut chutney, Cutlet

Foxtail millet articles Foxtail millet Research articles Foxtail millet review articles Foxtail millet PubMed articles Foxtail millet PubMed Central articles Foxtail millet 2023 articles Foxtail millet 2024 articles Foxtail millet Scopus articles Foxtail millet impact factor journals Foxtail millet Scopus journals Foxtail millet PubMed journals Foxtail millet medical journals Foxtail millet free journals Foxtail millet best journals Foxtail millet top journals Foxtail millet free medical journals Foxtail millet famous journals Foxtail millet Google Scholar indexed journals Laddu articles Laddu Research articles Laddu review articles Laddu PubMed articles Laddu PubMed Central articles Laddu 2023 articles Laddu 2024 articles Laddu Scopus articles Laddu impact factor journals Laddu Scopus journals Laddu PubMed journals Laddu medical journals Laddu free journals Laddu best journals Laddu top journals Laddu free medical journals Laddu famous journals Laddu Google Scholar indexed journals Panjeri articles Panjeri Research articles Panjeri review articles Panjeri PubMed articles Panjeri PubMed Central articles Panjeri 2023 articles Panjeri 2024 articles Panjeri Scopus articles Panjeri impact factor journals Panjeri Scopus journals Panjeri PubMed journals Panjeri medical journals Panjeri free journals Panjeri best journals Panjeri top journals Panjeri free medical journals Panjeri famous journals Panjeri Google Scholar indexed journals Kheer articles Kheer Research articles Kheer review articles Kheer PubMed articles Kheer PubMed Central articles Kheer 2023 articles Kheer 2024 articles Kheer Scopus articles Kheer impact factor journals Kheer Scopus journals Kheer PubMed journals Kheer medical journals Kheer free journals Kheer best journals Kheer top journals Kheer free medical journals Kheer famous journals Kheer Google Scholar indexed journals Peanut chutney articles Peanut chutney Research articles Peanut chutney review articles Peanut chutney PubMed articles Peanut chutney PubMed Central articles Peanut chutney 2023 articles Peanut chutney 2024 articles Peanut chutney Scopus articles Peanut chutney impact factor journals Peanut chutney Scopus journals Peanut chutney PubMed journals Peanut chutney medical journals Peanut chutney free journals Peanut chutney best journals Peanut chutney top journals Peanut chutney free medical journals Peanut chutney famous journals Peanut chutney Google Scholar indexed journals Cutlet articles Cutlet Research articles Cutlet review articles Cutlet PubMed articles Cutlet PubMed Central articles Cutlet 2023 articles Cutlet 2024 articles Cutlet Scopus articles Cutlet impact factor journals Cutlet Scopus journals Cutlet PubMed journals Cutlet medical journals Cutlet free journals Cutlet best journals Cutlet top journals Cutlet free medical journals Cutlet famous journals Cutlet Google Scholar indexed journals nutritive value articles nutritive value Research articles nutritive value review articles nutritive value PubMed articles nutritive value PubMed Central articles nutritive value 2023 articles nutritive value 2024 articles nutritive value Scopus articles nutritive value impact factor journals nutritive value Scopus journals nutritive value PubMed journals nutritive value medical journals nutritive value free journals nutritive value best journals nutritive value top journals nutritive value free medical journals nutritive value famous journals nutritive value Google Scholar indexed journals foods market articles foods market Research articles foods market review articles foods market PubMed articles foods market PubMed Central articles foods market 2023 articles foods market 2024 articles foods market Scopus articles foods market impact factor journals foods market Scopus journals foods market PubMed journals foods market medical journals foods market free journals foods market best journals foods market top journals foods market free medical journals foods market famous journals foods market Google Scholar indexed journals

Article Details

1. Introduction

Triggered by increasing industrialization, urbanization and the phenomenon of “Working women”, recent years have witnessed a spurt in the growth of the convenience foods market and breath-taking changes have taken place both in terms of quality and quantity (variety) of convenience products available, and the packaging as well as the processing technologies involved [1-2]. Among the minor millets, Foxtail millet has been tried by several workers in the development of various foods, which include bread [3], cakes [4], traditional foods [5-6], weaning foods [7-8], popped, extruded, roller-dried and flaked products [9], noodles [10]. The foxtail millet rice can be used instead of rice in the preparation of all the traditional products like bisibele bath, chakkali, pongal, dosa, idli, and laddus. Thus, besides its traditional use in making chapatti and porridge, millet can be exploited for the development of low GI therapeutic food products like biscuits. The nutritional composition of Foxtail millet per 100 gm is fat (4.3 gm), minerals (3 gm), protein (12.3 gm), calcium (31 mg %), carbohydrate (60.9 gm), phosphorous (290 mg%) and dietary fibre (14 gm). The amino acid profile is balanced and the dietary fiber content is very high compared to other cereals. Further studies are needed to determine long term effects of consumption of foxtail millet biscuits on blood lipid profile and glycosylated haemoglobin of diabetics and cardiovascular patients. Even though the nutritional qualities of millet have been well recorded [11], its utilization for food is confined to the traditional consumers in tribal populations, mainly due to non-availability of consumer-friendly, ready-to-use or ready-to-eat products, as are found for rice and wheat [12]. In recent times, there has been a renewed interest in millets. This study was conducted to incorporate foxtail millet in commonly consumed food recipes.

2. Materials and Methods

Foxtail millets were procured from a supermarket named BALAJI at Basheer bagh, Hyderabad. The raw materials required for the preparation of the products were procured from local markets of abids, Hyderabad.

2.1 Standardization of the recipe

Standardization is the process where a recipe is tested number of times and found a satisfactory quantity and yield. It is a gradual trial process. The standardization procedure was carried out by repeated trials till an acceptable recipe for the preparation of the product was obtained. The amounts were finalized by assessing the appearance, texture and taste of the variations. The finalized products were laddu, panjeri, kheer, cutlet, peanut chutney [5] (Figures 1-5 and Tables 1-5). Amounts of all the ingredients in the formulation of different products,

|

Basic |

Variation I |

Variation II |

|||

|

Ingredient |

Quantity |

Ingredient |

Quantity |

Ingredient |

Quantity |

|

Milk |

200 ml |

Milk |

200 ml |

Milk |

200 ml |

|

Rice |

30 g |

Rice |

20 g |

Rice |

10 g |

|

- |

- |

Foxtail Millet |

10 g |

Foxtail Millet |

20 g |

|

Sugar |

100 g |

Sugar |

100 g |

Sugar |

100 g |

|

Resin |

10 g |

Resin |

10 g |

Resin |

10 g |

|

Cashew |

10 g |

Cashew |

10 g |

Cashew |

10 g |

|

Ghee |

10 g |

Ghee |

10 g |

Ghee |

10 g |

Table 1: Ingredient and amount used in the development of Kheer.

|

Basic |

Variation I |

Variation II |

|||

|

Ingredient |

Quantity |

Ingredient |

Quantity |

Ingredient |

Quantity |

|

Peanuts |

30 g |

Peanuts |

20 g |

Peanuts |

10 g |

|

- |

- |

Foxtail Millet |

10 g |

Foxtail Millet |

20 g |

|

Cumin seeds |

10 g |

Cumin seeds |

10 g |

Cumin seeds |

10 g |

|

Curry Leaves |

10 g |

Curry Leaves |

10 g |

Curry Leaves |

10 g |

|

Oil |

5-10 ml |

Oil |

5-10 ml |

Oil |

5-10 ml |

Table 2: Ingredient and amount used in the development of Peanut Chutney.

|

Basic |

Variation I |

Variation II |

|||

|

Ingredient |

Quantity |

Ingredient |

Quantity |

Ingredient |

Quantity |

|

Potatoes |

200 g |

Potatoes |

150 g |

Potatoes |

100 g |

|

Onion |

50 g |

Onion |

50 g |

Onion |

50 g |

|

- |

- |

Foxtail Millet |

50 g |

Foxtail Millet |

100 g |

|

Coriander |

10 g |

Coriander |

10 g |

Coriander |

10 g |

|

Green Chilly |

10 g |

Green Chilly |

10 g |

Green Chilly |

10 g |

|

Oil |

20 ml |

Oil |

20 ml |

Oil |

20 ml |

Table 3: Ingredient and amount used in the development of Cutlet.

|

Basic |

Variation I |

Variation II |

|||

|

Ingredient |

Quantity |

Ingredient |

Quantity |

Ingredient |

Quantity |

|

Wheat Flour |

100 g |

Wheat Flour |

100 g |

Wheat Flour |

100 g |

|

Besan |

100 g |

Besan |

50 g |

Besan |

25g |

|

Sugar |

100 g |

Sugar |

100 g |

Sugar |

100 g |

|

- |

- |

Foxtail Millet |

150 g |

Foxtail Millet |

175 g |

|

Almonds |

50 g |

Almonds |

50 g |

Almonds |

50 g |

|

Ghee |

50 g |

Ghee |

50 g |

Ghee |

50 g |

|

Honey |

20g |

Honey |

20 g |

Honey |

20 g |

Table 4: Ingredient and amount used in the development of laddu.

|

Basic |

Variation I |

Variation II |

|||

|

Ingredient |

Quantity |

Ingredient |

Quantity |

Ingredient |

Quantity |

|

Powdered Almond |

50 g |

Powdered Almond |

50 g |

Powdered Almond |

50 g |

|

Powdered Cashew |

50 g |

Powdered Cashew |

50 g |

Powdered Cashew |

50 g |

|

- |

- |

Foxtail Millet |

50 g |

Foxtail Millet |

75 g |

|

Powdered Pista |

50 g |

Powdered Pista |

50 g |

Powdered Pista |

50 g |

|

Powdered Walnut |

50 g |

Powdered Walnut |

50 g |

Powdered Walnut |

50 g |

|

Sugar |

100 g |

Sugar |

100 g |

Sugar |

100 g |

|

Ghee |

100 g |

Ghee |

100 g |

Ghee |

100 g |

|

Powdered Makhana |

50 g |

Powdered Makhana |

50 g |

Powdered Makhana |

50 g |

Table 5: Ingredient and amount used in the development of Panjeri.

2.2 Method of preparation

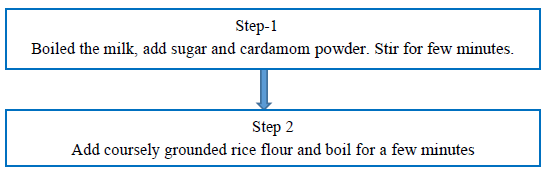

Figure 1: Method of preparation of Kheer (basic).

2.2.1 Variations: To the above recipe, soaked, roasted and coarsely grounded foxtail millet was added along with grounded rice flour in variation 1 and 2.

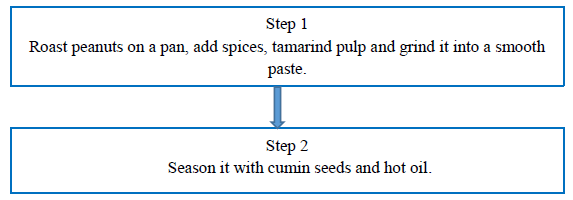

Figure 2: Method of preparation of Peanut Chutney (basic).

2.2.2 Variation: To the above recipe, soaked, roasted and finely grounded foxtail millet was added along with grounded peanuts in variation 1 and 2.

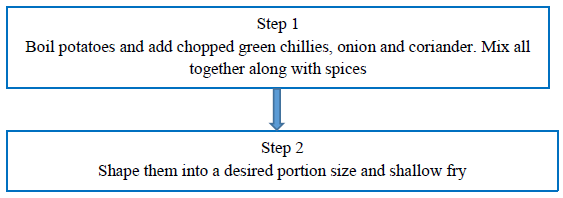

Figure 3: Method of preparation of Cutlet (basic).

2.2.3 Variation: To the above recipe, pressure-cooked and mashed foxtail millet was added along with potatoes in variation 1 and 2.

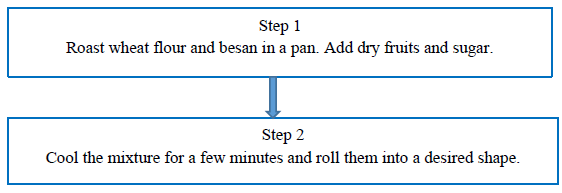

Figure 4: Method of preparation of Laddu.

2.2.4 Variation: To the above recipe, finely grounded foxtail millet was added along with wheat flour and besan of variation 1 and 2.

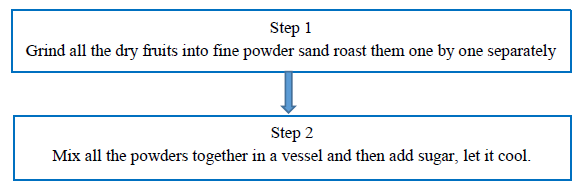

Figure 5: Method of preparation of Panjeri (basic).

2.2.5 Variation: To the above recipe, finely grounded and roasted foxtail millet was added along with other dry fruit powders in variation 1 and 2.

2.3 Sensory evaluation of the developed products

The sensory evaluation of the five developed samples (laddu, kheer, panjeri, cutlet, peanut chutney) was carried out by 38 semi-trained panelists for numerical scoring and 51 semi-trained panelists made hedonic evaluation of the samples and were asked to assess the laddu, kheer, panjeri, peanut chutney for overall acceptability based on the appearance, color, taste, flavor and texture.

3. Results and Discussion

It was found that the mean score of kheer for color of variation 2 (8.27 ± 0.85) was greater than variation 1( 8.10 ± 0.03). The flavor of variation 2 (8.02 ± 0.95) was greater than variation 1 (7.82 ± 0.95). The texture of variation 2 (8.06 ± 0.88) was greater than variation 1 (8.20 ± 1.02). The taste of variation 2 (8.02 ± 0.95) was greater than variation 1 (7.86 ± 0.96). The overall acceptability of variation 2 (8.10 ± 0.92) was greater than variation 1 (7.96 ± 0.85). The data was analyzed using analysis of variance ANOVA test and the calculated value is (11.60) which is more than the table value. Hence, there was significant difference observed at 1% and 5% level of significance. The mean score for peanut chutney given by the panelists for color for variation 1 (8.14 ± 0.72) is greater than variation 2 (8.06 ± 0.92). The flavor of variation 1 (7.96 ± 0.75) is greater than variation 2 (7.92 ± 0.91). The texture where variation 1 (8.04 ± 0.80) is greater than variation 2 (7.92 ± 1.06). The taste where variation 1 (8.06 ± 0.79) is greater than variation 2 (7.82 ± 0.93). The overall acceptability for variation 1 (8.10 ± 0.76) is greater than variation 2 (7.94 ± 0.95). The data was analyzed using analysis of variance ANOVA test and the calculated value is (0.014) which is less than the table value. Hence, there was no significant difference observed at 1% and 5% level of significance.

The mean score of laddu given by the panelists for color where variation 2 (8.63 ± 0.63) is greater than variation 1 (8.41 ± 0.64). The flavor of variation 2 (8.63 ± 0.60) was greater than variation 1 (8.27 ± 0.78). The texture of variation 2 (8.59 ± 0.73) was greater than variation 1 (8.33 ± 0.71). The taste of variation 2 (8.65 ± 0.63) was greater than variation 1 (8.31 ± 0.79). The overall acceptability of variation 2 (8.75 ± 0.52) was greater than variation 1 (8.33 ± 0.65). The data was analyzed using analysis of variance ANOVA test and the calculated value is (10.9) which is more than the table value. Hence, there was significant difference observed at 1% and 5% level of significance. The mean score of panjeri given by the panelists for color of variation 2 (8.47 ± 0.83) was greater than variation 1 (8.33 ± 0.79). The flavor of variation 2 (8.22 ± 0.90) was greater than variation 1 (8.04 ± 1.00). The texture of variation 2 (8.35 ± 0.89) was greater than variation 1 (8.20 ± 0.87). The taste of variation 2 (8.33 ± 0.86) was greater than variation 1 (8.08 ± 1.00). The overall acceptability of variation 2 (8.37 ± 0.85) was greater than variation 1 (8.16 ± 0.83). The data was analyzed using analysis of variance ANOVA test and the calculated value is (0.03) which is less than the table value. Hence, there was no significant difference observed at 1% and 5% level of significance.

4. Conclusion

It was concluded that all the products that were developed were calculated for energy, protein, fat, carbohydrate, iron and calcium. Consumption of these nutrient dense products will not only improve the nutritional status of the population, but also sustain the production of minor millets, which are on the extinct, ultimately leading to a more holistic approach in sustaining precious agro bio-diversity. It’s promising nutritional facts gives warranty for further studies to increase the dietary use of these food products. Hence, a bright future is envisaged for use of Foxtail millet in convenience foods, particularly traditional convenience mixes to meet the challenges of the modern dynamic food industry.

References

- Ray KS and Athawale MP. Index of nutritional quality (INQ) of some selected Indian snacks. The Indian Journal of Nutrition and Dietetics 38 (2001): 114-118.

- Arya SS. Convenience Foods-Emerging Scenario. Indian Food Industry 11 (1992): 31-41.

- Thiam AA and Ndoye A. Bread from millet. League for International Food Education Newsletter (1977).

- Joshi HC, Singh G, Agarwal P, et al. Effect of incorporation of Foxtail millet (Setaria italica) on the quality of cake. Souvenir, 5th International Food Convention, Innovative Food Technologies and quality systems, strategies for global competitiveness (2003): 99-100.

- Aruna K. Nutrient content and acceptability of selected recipes made with Italian millet. Journal of Research APAU 17 (1989): 28-32.

- Hima Bindu N and Sumathi S. Organoleptic evaluation and nutrient composition of Foxtail millet products. Souvenir, 5th International Food Convention, Innovative Food Technologies and quality systems, strategies for global competitiveness (2003): 121.

- Gahlawat P and Sehgal S. Protein quality of weaning foods based on locally available cereal and pulse combination. Plant foods for human nutrition 46 (1994): 245-253.

- Thathola A and Srivastava S. Physico-chemical properties and nutritional traits of millet-based weaning food suitable for infants of the Kumaon hills, Northern India. Asia Pacific Journal of Clinical Nutrition 11 (2002): 28-32.

- Ushakumari SR, Shrikantan Latha and Malleshi NG. The functional properties of popped, flaked, extruded and roller-dried Foxtail millet (Setaria italica). International Journal of Food Science and Technology, 39 (2004): 907-915.

- Sowbhagya CM and Ali SZ. A process for manufacturing high fibre, low fat vermicelli noodles from millets. Indian Patent 1128/DEL/99 (1999).

- Hulse JH, Laing EM and Pearson OE. Sorghum and the millets: theirmcomposition and nutritive value. Academic press, London (1980).

- Malleshi NG and Desikachar HSR. nutritive value of malted millet flours, qual plant plant foods Hum nutr. 36 (1986): 191-196.