Development of an Electrocautery Surface Coating Method to Suppress Surgical Smoke

Article Information

Takayuki Tokoroyama1*, Motoyuki Murashima2 , Koki Ogawa1, Noritsugu Umehara1, Hosei Nagano1, Takayuki Yorozu3, Junichi Uchida3

1Nagoya University, Mechanical and Aerospace Engineering, Furo cho, Chikusa ku, Nagoya, Aichi 4648603 Japan

2Tohoku University, Mechanical Systems Engineering, 6 6 01, Aoba, Aramaki aza, Sendai, Miyagi, 9808579 Japan

3Nihon Parkerizing, Central Research Laboratories, 4, 2784, Hiratsuka shi, Kanagawa, 2540012 Japan

*Corresponding Author: Takayuki Tokoroyama, Nagoya University, Mechanical and Aerospace Engineering, Furo cho, Chikusa ku, Nagoya, Aichi 464 8603 Japan

Received: 19 December 2023; Accepted: 26 December 2023; Published: 02 February 2024

Citation: Takayuki Tokoroyama, Motoyuki Murashima, Koki Ogawa, Noritsugu Umehara, Hosei Nagano, Takayuki Yorozu, Junichi Uchida. Development of an Electrocautery Surface Coating Method to Suppress Surgical Smoke. Journal of Surgery and Research. 7 (2024): 53-59.

View / Download Pdf Share at FacebookAbstract

Background: The effectiveness of silicone coatings in preventing coagulated blood adhesion has already been established; however, the coatings’ influence on the generation of surgical smoke has yet to be elucidated, and their effectiveness in preventing surgical smoke has yet to be examined.

Methods: In an electrical circuit model, a proposed model of increased electrical resistance due to coagulated blood adhesion encompasses the electrode, silicone coating, and discharge target. To investigate the viability of an electrocautery surface coating that suppresses surgical smoke, smoke generation was analyzed via discharge experiments using electrocautery tip electrodes with different cross sectional shapes and electrodes with no coating. The effect of increasing electrical resistance on the amount of smoke generated was also investigated by using a high speed infrared camera to measure the temperature change in the area of the electrode tip during the discharge.

Results: The different coated electrodes A (fully covered and thicker than B), B (fully covered), C (side exposed), and uncoated electrode D were evaluated for the amount of smoke generation during discharge. The particle counts for coated electrodes A, B, and D showed approximately 5236, 10328, 812, and 5032 counts/L in 5 s, respectively. Conversely, electrode C showed approximately 812 counts/L, which was 92% lower than the other.

Conclusions: The electrical circuit model was suggested, and the side exposed electrode can limit the generation of surgical smoke.

Keywords

Electrocautery, Side exposed type electrode, Silicone coating, Suppression of coagulated blood, Surgical smoke

Electrocautery articles; Side exposed type electrode articles; Silicone coating articles; Suppression of coagulated blood articles; Surgical smoke articles

Electrocautery articles Electrocautery Research articles Electrocautery review articles Electrocautery PubMed articles Electrocautery PubMed Central articles Electrocautery 2023 articles Electrocautery 2024 articles Electrocautery Scopus articles Electrocautery impact factor journals Electrocautery Scopus journals Electrocautery PubMed journals Electrocautery medical journals Electrocautery free journals Electrocautery best journals Electrocautery top journals Electrocautery free medical journals Electrocautery famous journals Electrocautery Google Scholar indexed journals Side exposed type electrode articles Side exposed type electrode Research articles Side exposed type electrode review articles Side exposed type electrode PubMed articles Side exposed type electrode PubMed Central articles Side exposed type electrode 2023 articles Side exposed type electrode 2024 articles Side exposed type electrode Scopus articles Side exposed type electrode impact factor journals Side exposed type electrode Scopus journals Side exposed type electrode PubMed journals Side exposed type electrode medical journals Side exposed type electrode free journals Side exposed type electrode best journals Side exposed type electrode top journals Side exposed type electrode free medical journals Side exposed type electrode famous journals Side exposed type electrode Google Scholar indexed journals Silicone coating articles Silicone coating Research articles Silicone coating review articles Silicone coating PubMed articles Silicone coating PubMed Central articles Silicone coating 2023 articles Silicone coating 2024 articles Silicone coating Scopus articles Silicone coating impact factor journals Silicone coating Scopus journals Silicone coating PubMed journals Silicone coating medical journals Silicone coating free journals Silicone coating best journals Silicone coating top journals Silicone coating free medical journals Silicone coating famous journals Silicone coating Google Scholar indexed journals Suppression of coagulated blood articles Suppression of coagulated blood Research articles Suppression of coagulated blood review articles Suppression of coagulated blood PubMed articles Suppression of coagulated blood PubMed Central articles Suppression of coagulated blood 2023 articles Suppression of coagulated blood 2024 articles Suppression of coagulated blood Scopus articles Suppression of coagulated blood impact factor journals Suppression of coagulated blood Scopus journals Suppression of coagulated blood PubMed journals Suppression of coagulated blood medical journals Suppression of coagulated blood free journals Suppression of coagulated blood best journals Suppression of coagulated blood top journals Suppression of coagulated blood free medical journals Suppression of coagulated blood famous journals Suppression of coagulated blood Google Scholar indexed journals Surgical smoke articles Surgical smoke Research articles Surgical smoke review articles Surgical smoke PubMed articles Surgical smoke PubMed Central articles Surgical smoke 2023 articles Surgical smoke 2024 articles Surgical smoke Scopus articles Surgical smoke impact factor journals Surgical smoke Scopus journals Surgical smoke PubMed journals Surgical smoke medical journals Surgical smoke free journals Surgical smoke best journals Surgical smoke top journals Surgical smoke free medical journals Surgical smoke famous journals Surgical smoke Google Scholar indexed journals postdischarge observation articles postdischarge observation Research articles postdischarge observation review articles postdischarge observation PubMed articles postdischarge observation PubMed Central articles postdischarge observation 2023 articles postdischarge observation 2024 articles postdischarge observation Scopus articles postdischarge observation impact factor journals postdischarge observation Scopus journals postdischarge observation PubMed journals postdischarge observation medical journals postdischarge observation free journals postdischarge observation best journals postdischarge observation top journals postdischarge observation free medical journals postdischarge observation famous journals postdischarge observation Google Scholar indexed journals laser and ultrasonic scalpels articles laser and ultrasonic scalpels Research articles laser and ultrasonic scalpels review articles laser and ultrasonic scalpels PubMed articles laser and ultrasonic scalpels PubMed Central articles laser and ultrasonic scalpels 2023 articles laser and ultrasonic scalpels 2024 articles laser and ultrasonic scalpels Scopus articles laser and ultrasonic scalpels impact factor journals laser and ultrasonic scalpels Scopus journals laser and ultrasonic scalpels PubMed journals laser and ultrasonic scalpels medical journals laser and ultrasonic scalpels free journals laser and ultrasonic scalpels best journals laser and ultrasonic scalpels top journals laser and ultrasonic scalpels free medical journals laser and ultrasonic scalpels famous journals laser and ultrasonic scalpels Google Scholar indexed journals health hazard articles health hazard Research articles health hazard review articles health hazard PubMed articles health hazard PubMed Central articles health hazard 2023 articles health hazard 2024 articles health hazard Scopus articles health hazard impact factor journals health hazard Scopus journals health hazard PubMed journals health hazard medical journals health hazard free journals health hazard best journals health hazard top journals health hazard free medical journals health hazard famous journals health hazard Google Scholar indexed journals surgical smoke generation articles surgical smoke generation Research articles surgical smoke generation review articles surgical smoke generation PubMed articles surgical smoke generation PubMed Central articles surgical smoke generation 2023 articles surgical smoke generation 2024 articles surgical smoke generation Scopus articles surgical smoke generation impact factor journals surgical smoke generation Scopus journals surgical smoke generation PubMed journals surgical smoke generation medical journals surgical smoke generation free journals surgical smoke generation best journals surgical smoke generation top journals surgical smoke generation free medical journals surgical smoke generation famous journals surgical smoke generation Google Scholar indexed journals surgeon articles surgeon Research articles surgeon review articles surgeon PubMed articles surgeon PubMed Central articles surgeon 2023 articles surgeon 2024 articles surgeon Scopus articles surgeon impact factor journals surgeon Scopus journals surgeon PubMed journals surgeon medical journals surgeon free journals surgeon best journals surgeon top journals surgeon free medical journals surgeon famous journals surgeon Google Scholar indexed journals

Article Details

Introduction

Electrocautery is one of the most used medical devices. The electrocautery system consists of a high frequency power source, an electrocautery tip electrode that applies a concentrated current to the living tissue, and a counter electrode plate that collects the current from the living tissue. The application of AC voltage to the closed circuit of this system and biological tissue generates Joule heat, causing a steam explosion of intracellular water to make an incision and thermal coagulation of blood proteins to stop bleeding. Electrocautery is critical in today's surgical practice since it contributes to less blood loss and quicker operative times, with the advantage of performing both incision and hemostasis with a single device. An existing challenge with electrocautery is that coagulated blood and tissue markings on the tip electrode might obstruct the discharge and diminish the electrocautery’s performance. By contrast, electrodes with silicone coating on the electrode tip surface are commercially available. Silicon coating on the tip surface suppresses scorching during discharge, improves the wiping off of adhered coagulated blood, and makes it possible to perform incision and hemostasis by discharge without adhesion of biological tissue and blood on the electrode tip surface. In addition, silicone based polymers, used as coating materials, have high biocompatibility. The change in electrical energy with discharge time is modest; they are commonly applied in surgical operations. However, silicone based polymers have low electrical and thermal conductivity, which may induce a rise in electrical resistance and temperature around the electrode. Previously, the authors investigated the impact of coating coverage on the electrical properties during discharge and the ability of the electrode to transmit blood using electrodes with different coating patterns and electrodes without coatings [1]. The results demonstrated that removing a portion of the coating to expose the metal surface lowered electrical resistance and increased temperature. Furthermore, it was discovered that by lowering the maximum temperature of the electrode tip surface the wiping force of coagulated blood could be lowered. However, smoke is generated from the discharge site when electrocautery is used, and it is problematic for the surgeon because it blocks his/her vision and poses a health hazard [2]. This smoke is called surgical smoke and has been reported to contain not only chemicals such as hydrocarbons, phenols, nitriles, and fatty acids but also carbonized living tissue, viable bacteria, and viruses [3-6]. With the spread of novel coronavirus infections, the risk of exposure to coronavirus disease 2019 (COVID-19) via surgical smoke has also been noted [7,8]. Surgical smoke particles generated by electrocautery are smaller than those produced by laser and ultrasonic scalpels [3,4], making it challenging to entirely prevent them with widely used surgical masks. Although smoke evacuation devices are applied in current surgical operations, there are still problems, such as interference with surgical operations and the need to replace filters due to blood suction. Methods to control the generation of surgical smoke are needed. Thus, we focused on the surface coating of the electrocautery tip mentioned above. The effectiveness of silicone coatings in preventing the adhesion of coagulated blood has already been demonstrated, the influence of the coatings on the generation of surgical smoke has yet to be elucidated, and their effectiveness in preventing surgical smoke has yet to be investigated. In this study, to examine the feasibility of an electrocautery surface coating that suppresses surgical smoke, discharge experiments were performed utilizing electrocautery tip electrodes with coatings of different cross sectional shapes and electrodes with no coating. In an electrical circuit model, a proposed model of increased electrical resistance owing to coagulated blood adhesion encompasses the electrode, silicone coating, and discharge target. The effect of increasing electrical resistance on smoke generation was examined. The mechanism by which the surface coating of the electrocautery tip affects smoke generation was investigated by using a high-speed infrared camera to measure the temperature change in the vicinity of the electrode tip during the discharge.

2. Specimen and experimental procedure

2.1 Coatings on the tips

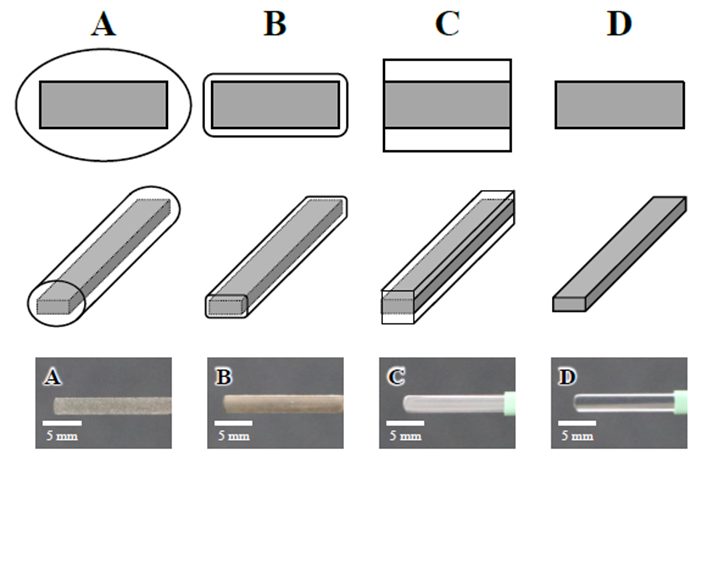

To clarify the impact of electrocautery surface coating on surgical smoke generation, three commercially available electrocautery tip electrodes with silicone coating were utilized. They are referred to as electrodes A, B, and C, respectively. In electrodes A and B, all metal surfaces are coated; however, in electrode C, the side surface of the electrode is not coated, leaving the metal surface exposed. The coating thicknesses are 155, 33, and 180 μm for A, B, and C, respectively. An uncoated electrocautery tip electrode was used for comparison -the so-called D. Figure 1 shows the photographs and schematic diagrams of each electrode specimen. The electrode material is SUS304 stainless steel, and the coating material is a silicone based polymer.

Figure 1: Photograph and schematic of coated electrode specimen

2.2 Discharge target

Porcine blood was used as the discharge target to simulate the electrocautery discharge conditions in actual surgical procedures. Porcine blood was refrigerated at approximately 8 °C to maintain freshness and used within 1 week of collection.

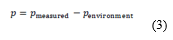

2.3 Electrocautery discharge tests and methods for evaluating smoke generation

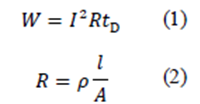

To evaluate the amount of surgical smoke generated during electrocautery discharge, an electrocautery device and a particle counting device were utilized. Figure 2 shows a schematic diagram of the system. The electrocautery device consists of a series circuit consisting of an electrocautery power supply unit, electrocautery tip electrode, discharge target, and counter electrode plate. The amount of heat generated is expressed in equations (1) and (2).

Where W [J] is the amount of heat generated, I [A] is the effective current, R [Ω] is the electrical resistance of the biological tissue, and tD [s] is the discharge time. The electrical resistance R of the biological tissue is calculated from the electrical resistivity of the tissue ρ [Ω/cm], the cross-sectional area of the current path A [cm2], and the length l [cm]. To accurately control the discharge time tD, a discharge control system was used to enable control of discharge and non-discharge in 1 ms increments. The discharge time is controlled by sending control commands from a personal computer to a microcomputer (Arduino Uno), which is then connected or disconnected via a relay device (G5NB 1A DC5V, Omron). The pencil type electrocautery that holds the tip electrode is attached to the electrocautery holder, and the position of the holder can be adjusted in 10 μm increments using a micrometer feed screw. This allows for adjustment of the electrode’s insertion depth into the blood. The discharge target was set on a counter plate in a stainless steel container. In this experiment, the discharge times tD was set to 1, 3, and 5 s, the power supply output P to 30 W, the power supply frequency f to 500 kHz, and the electrode insertion depth d to the discharge target to 2 mm.

Figure 2: Schematic diagram of the particle counting system

The particle counting equipment was a light scattering particle counter (MET ONE HHPC 6+, Beckman Coulter). A light scattering particle counter was set 50 cm above the electrometallic discharge device in this experiment to count the number of particles per unit volume. The rated flow rate was 2.83 L/min, and the particle diameters measured were 0.5, 1.0, 2.0, and 5.0 μm. This is because particles with a size of 0.5-5.0 μm are called lung damaging dust and reach the periphery of the lungs, causing acute and chronic inflammatory changes [2]. The measurement time was set to 30 s from the start of discharge. To eliminate the influence of particles in the experimental environment, the number of particles per unit volume in the experimental environment was measured three times before the discharge started. The smoke generation rate p was calculated by subtracting the average number of particles per unit volume in the environment from the number of particles pmeasured during discharge. Therefore, the amount of smoke generated is evaluated by the following equation (3).

2.4 Methods for measuring and analyzing electrical characteristics during discharge

An oscilloscope (TBS2072, Tektronix) was used to measure electrical characteristics during electrocautery discharge. In this experiment, the oscilloscope was connected to a voltage probe (P5002A, Tektronix) and a current probe (P6021A, Tektronix) on the circuit of the discharge device to measure the voltage and current during discharge. Since the power supply frequency was 500 kHz, the sampling frequency was set to 3.125 MHz based on the sampling theorem. Because the voltages and currents are alternating currents, the measurement results are discrete values that oscillate positively and negatively. Therefore, in this study, the practical values of the nth voltage and current, fe(n), were calculated using the nth measurement value, f(n), and a constant number of measurement points, N, by the following equation (4):

where N= 31,250 (0.01 s). The quotient of the voltage and current calculated from equation (4) was used as the electrical resistance value.

2.5 Method of measuring temperature distribution during discharge

During electrocautery discharge, an infrared high-speed camera (X6901sc, Photron) was used to measure the temperature distribution. In this experiment, a 1× magnification, 200 mm focal length objective lens was used to measure the temperature distribution of the liquid surface near the electrode insertion point during discharge by taking images from an angle of attack of approximately 45° to the liquid surface of the discharge target. The number of pixels captured was 640×512 pixels, the resolution of one pixel was 25 μm, the shooting speed was 300 fps, and the measurement temperature range was 35°C-350°C.

3. Results

3.1 Results of smoke generation measurements during discharge tests utilizing each electrode specimen

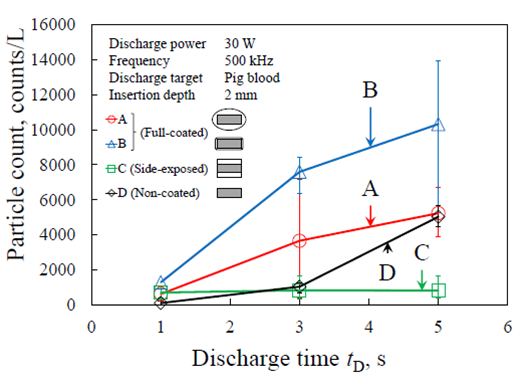

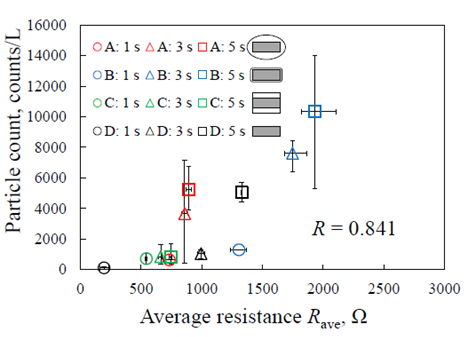

Figure 3 showed the measured smoke generation during discharge when discharge tests were conducted with coated electrodes A, B, and C and uncoated electrode D with discharge times tD=1, 3, and 5 s. The number of particles per unit volume at tD=1 s was approximately 618, 1286, 703, and 101 counts/L for each electrode, respectively. Electrode B showed the highest value, followed by electrodes A and C, with identical values. The particle counts at tD= 3 s were approximately 3660, 7602, 829, and 1037 counts/L, respectively. The number of particles at electrodes A and B increased by approximately 5.9-fold compared to the case tD= 1 s, with electrode B having the most significant value as in the case tD= 1 s. The number of particles at electrode D increased approximately 10.2-fold compared to the case tD= 1 s. However, the number of particles at electrode C increased only approximately 1.2-fold compared to the case tD= 1 s. Electrodes C and D had identical values. Moreover, the number of particles at electrode C increased only approximately1.2-fold compared to the case tD= 1 s. Furthermore, the particle count at tD= 5 s were approximately 5236, 10328, 812, and 5032 counts/L, respectively. The number of particles at electrodes A and B increased by 1.4-fold when compared to the case tD= 3 s, with electrode B having the most significant value as in both tD= 1 and 3 s. The number of particles at electrode D increased approximately 4.9-fold compared with the case tD= 3 s and was comparable with the value at electrode A. The number of particles at electrode C remained constant, meaning it did not increase. Consequently, at tD= 5 s, the number of particles at electrode C was 84%-92% lower than at the other electrodes. The results show that electrode C, whose side surface is not coated, has the most significant surgical smoke reduction impact.

Figure 3: Total amount of smoke generated by each electrode

3.2 Measurement results of electrical characteristics during discharge using each coated electrode specimen

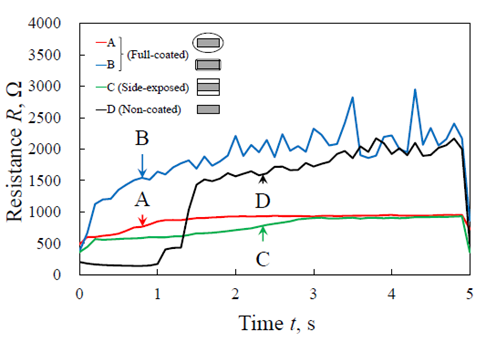

Figure 4 shows the measured electrical resistance of coated electrodes A, B, and C and uncoated electrode D during discharge testing with a discharge time of tD= 5 s.The electrical resistance of electrode A gradually increased soon after the initiation of the discharge and remained steady at approximately 940 Ω after t= 2.0 s. The electrical resistance of electrode B increased rapidly immediately after the start of discharge and continued to increase slowly until the end of discharge, reaching a maximum of approximately 2900 Ω. The electrical resistance of electrode C increased slowly soon after the initiation of the discharge and remained steady at approximately 920 Ω after t= 2.9 s.The electrical resistance of electrode D remained stable at approximately 150 Ω from the start of discharge until t= 1.0 s, after which it increased rapidly until t= 1.5 s and continued to increase slowly until the end of discharge, reaching a maximum value of approximately 2200 Ω.

Figure 4: Time variation of electrical resistance of each electrode

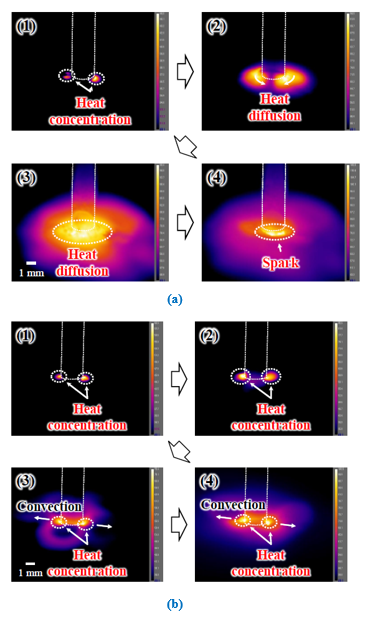

3.3 Observation results during discharge using an infrared high-speed camera using each electrode specimen

The temperature distribution results observed by a high-speed infrared camera during discharge and specimen observation after discharge are shown in figure 5 (a) and (b), respectively. The discharge tests were conducted using an uncoated electrode D and a coated electrode C whose electrode side surface was not covered with a coating, with a discharge time tD= 5 s. When electrode D was used, the heat was concentrated on the electrode’s side surface immediately after the discharge started to t= 1.1 s. Then the heat was transferred from the side surface to the flat surface of the electrode from t= 1.4 s onward. Bubbles were observed near the electrode insertion point from t= 1.2 s to 2.8 s. Additionally, a severe arc-like heating phenomenon was detected at the entire electrode insertion point after t= 2.9 s. The bubbles were observed to be generated by the electrode insertion point, as well as the electrode insertion area from t = 2.9 s onward. The maximum temperature in the vicinity of the electrode insertion area increased gradually immediately after the discharge began, reaching approximately 120 ºC at t= 1.3 s and remaining stable at approximately 100°C until t= 2.8 s. When an arc-like heat-generating phenomenon was detected at the electrode insertion point, a maximum temperature peak of around 280°C was observed. Furthermore, the whole surface of the electrode was coated with coagulated blood after the discharge. When electrode C was utilized, however, heat was concentrated on the side surface of the electrode from the start of discharge to the end of discharge, and heat was observed to be transmitted from the side surface of the electrode to the flat surface of the electrode. Additionally, heat convection outward from the electrode’s side face was observed after time t= 2.0 s. Furthermore, from the beginning to the completion of the discharge, the side surface of the electrode was hotter than the flat surface of the electrode. The maximum temperature around the electrode insertion area increased rapidly after discharge began, reaching approximately 90 ºC at t= 0.9 s and remaining stable at approximately 80 ºC until t= 4.2 s. Following the discharge, the uncoated side surface of the electrode and the electrode tip were found to be sparsely coated with coagulated blood.

Figure 5: (a) Results of infrared high-speed camera observation of electrode D and (b) electrode C

4. Discussion

4.1 Effect of electrical resistance during discharge on the amount of smoke generated

The side surface of the electrode was not coated after the discharge, where as the tip of the electrode was sparsely coated with coagulated blood. The influence of electrical resistance during discharge on the amount of smoke generated during discharge experiments utilizing coated electrodes A, B, and C and uncoated electrode D is discussed based on the experimental results. Figure 6 shows the average electrical resistance under each experimental setting. Both metrics showed a strong positive relationship with a correlation coefficient of R= 0.841. This implies that the increase in electrical resistance during discharge has a significant influence on the amount of smoke generated and that the amount of smoke generated can be minimized by suppressing the increase in electrical resistance during discharge.

Figure 6: Relationship between average electrical resistance and surgical smoke generation for each experimental condition

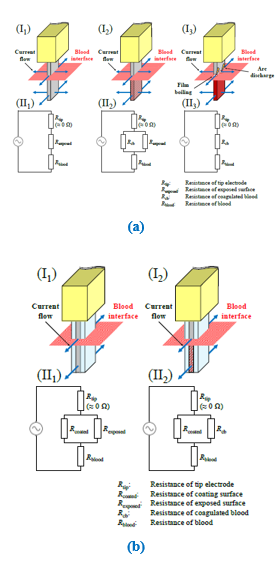

4.2 Effect of coating geometry on electrical properties and smoke generation during discharge

Based on the experimental results, the influence of the coating shape on the electrical resistance during discharge is discussed when discharge tests are conducted using coated electrode C, whose electrode side surface is not covered with a coating, and uncoated electrode D. Figure 7 shows a schematic diagram of the electrical resistance rising model and an electrical circuit model when discharge experiments with electrodes C and D were conducted. In the case of electrode D, the temperature distribution observation results shown in figure 5 confirm that heat was transferred from the electrode’s side surface to the electrode’s flat surface, and bubbles were generated from the electrode insertion area. It was also confirmed that intense arc discharges occurred over the entire electrode insertion area after the middle stage of the discharge. This suggests that the transition from a boiling state to film boiling caused the formation of a vapor film on the electrode surface, which became an insulating layer, resulting in the generation of arc discharges. Furthermore, the postdischarge observation results confirmed that coagulated blood coated the whole surface of the electrode. This implies that the coagulated blood attached to the flat surface of the electrode from the side surface and formed an electrical resistance layer, increasing electrical resistance and Joule heat. The afore mentioned reasons have increased the amount of smoke generated. In the case of electrode C, the temperature distribution observation results shown in figure 5 confirm that heat convection flowed outward from the side surface of the electrode during the discharge. The postdischarge observation results confirmed that the side surface of the electrode during the discharge. The postdischarge observation results confirmed that the side surface of the electrode, which is not covered by the coating, and the tip of the electrode, were slightly coated with coagulated blood. The exposed metal surface of the electrode’s side face enhanced thermal convection, causing bubbles to detach from the electrode insertion area and preventing the transition to film boiling. This is considered to have suppressed the transition to film boiling, preventing an increase in Joule heat and the generation of arc discharge, and therefore reducing the amount of smoke generated.

Figure 7: (a) Electrical resistance schematic diagram and circuit model of electrode D and (b) electrode C

5. Conclusions

In this study, to investigate the feasibility of an electrocautery surface coating that suppresses surgical smoke, we evaluated the amount of smoke generated by discharge tests using an electrocautery tip electrode with a coating of different cross-sectional shapes and an uncoated electrode and proposed a model of increased electrical resistance due to coagulated blood adhesion in an electrical circuit model that included the electrode, silicone coating, and discharge target. The effect of increasing electrical resistance increase on the amount of smoke generated was evaluated. The method by which the electrocautery surface coating affects smoke generation was explored using a high-speed infrared camera to measure the temperature change in the region of the electrode during the discharge. The following are the significant results obtained.

(1) Discharge tests were conducted utilizing coated electrodes A, B, and C and uncoated electrode D with varied coating geometries, and the amount of smoke generated during discharge was evaluated by measuring the number of particles per unit volume. The particle counts for coated electrodes A and B and uncoated electrode D at discharge time tD= 5 s were approximately 5236, 10328, 812, and 5032 counts/L, respectively. Nonetheless, the number of particles on coated electrode C, whose side surface was not coated, was 812 counts/L, which is approximately 92% lower than the number of particles of other electrodes. This indicates that electrode C has the most significant smoke reduction effect.

(2) Discharge tests were conducted, and the electrical resistance during discharge was determined. Coated electrodes A and B and uncoated electrodes D’s electrical resistance were 940, 2900, and 2200 Ω, respectively. However, the electrical resistance of coated electrode C reached approximately 940 Ω. The increase in electrical resistance was suppressed compared with other electrodes. A significant positive correlation coefficient R = 0.841 was obtained between the average electrical resistance and the amount of smoke generated under each experimental condition. This indicates that the electrical resistance during discharge has a significant impact on the amount of smoke emitted. Therefore, it was established that the amount of smoke generation could be reduced by suppressing the increase in electrical resistance during discharge.

(3) The mechanism of smoke reduction at the coated electrode was examined by observing the temperature distribution using a high-speed infrared camera during discharge. When electrode C was used, outward heat convection was detected from the side surface of the electrode during discharge. This is probably due to the concentration of current and heat on the electrode’s side face of the electrode’s metal surface of the side face of the electrode was exposed, which increases the current density. This suppressed the transition of the boiling state to film boiling and the growth of coagulated blood and suppressed the increase in electrical resistance, which lowered the amount of smoke generated.

Disclosure

Approval of the research protocol: N/A

Informed Consent: N/A

Registry and Registration No. of the study/Trial: N/A

Animal Studies: N/A

Conflict of interest: The authors declare no conflicts of interest associated with this manuscript.

References

- Tokoroyama T, Kobayashi M, Murashima M, et al. Preventing coagulated-blood adhesion on a coated electrosurgical knife. Transactions of the JSME 86 (2020): 20-00273.

- Alp E, Bijl D, Bleichrodt RP, et al. Surgical smoke and infection control. J. Hosp. Infect 62 (2006): 1-5.

- Ulmer BC. Air Quality in the Operating Room. Surg. Serv. Manag 3 (1997): 14-16.

- Ulmer BC. The Hazards of Surgical Smoke. AORN J 87 (2008): 721-734.

- Barrett WL, Garber SM. Surgical smoke: a review of the literature. Surg. Endosc 17 (2003): 979-987.

- Fitzgerald JEF, Malik M, Ahmed I. A single-blind controlled study of electrocautery and ultrasonic scalpel smoke plumes in laparoscopic surgery. Surg. Endosc 26 (2012): 337-342.

- Chadi SA, Guidolin K, Caycedo-Marulanda A, et al. Current evidence for minimally invasive surgery during the COVID-19 pandemic and risk mitigation strategies. Ann. Surg 272 (2020): e118-e124.

- George R, Robert U, Rami I, et al. Minimizing the risk of aerosol contamination during elective lung resection surgery. Ann. Surg 272 (2020): e125-e128.