Biogas Production from Olive Mill Wastewater: Biotechnological Development for Circular Economy

Article Information

Uri Marchaim1*, Dan Levanon1,2

1Migal, Galilee Research Institute, Tarshish 2, Kiryat Shmona, 1101600, Israel

2Faculty of Sciences and Technology, Tel-Hai College, Upper Galilee, 1220800, Israel

*Corresponding authors: Uri Marchaim, Migal, Galilee Research Institute, Tarshish 2, Kiryat Shmona, 1101600, Israel.

Received: 17 July 2025; Accepted: 21 July 2025; Published: 25 July 2025

Citation: Uri Marchaim, Dan Levanon. Biogas Production from Olive Mill Wastewater: Biotechnological Development for Circular Economy. Journal of Biotechnology and Biomedicine. 8 (2025): 287-298.

View / Download Pdf Share at FacebookAbstract

This study presents a full-scale approach to treat olive mill wastewater (OMW), reducing pollution through thermophilic anaerobic fermentation, yielding biogas for electricity and heat, slurry to substitute for peat moss, and partially purified wastewater for irrigation. These outputs align with the EU’s Green Deal strategy by supporting energy independence, wastewater valorization, and climate change mitigation. As a result of the pilot treatment, 93% reduction in chemical oxygen demand (COD) levels and 91% reduction in polyphenols was achieved. OMW slurries can substitute at least 30% of the peat moss in lettuce cultivation. In the economic theoretical analysis performed, we estimated the costs and profit, based on pilot expenses, and found that a full-scale regional central facility can achieve a positive net present value (NPV) (€1,239,234) and high internal rate of return (IRR) (42.49%). In the context of the circular economy out-lined here, collaboration among olive oil producers and the local wastewater utility, using OMW for bioenergy and utili-zation of all outputs, can lead to innovative regional business models. We offer a framework for developing sustainable, regionally adapted bioenergy business models and assesses critical variables affecting stakeholder cooperation and pro-ject viability.

Keywords

Biogas production; Olive mill wastewater (OMW); Circular economy; Sustainable bioenergy; Economic modeling

Biogas production articles; Olive mill wastewater (OMW) articles; Circular economy articles; Sustainable bioenergy articles; Economic modeling articles

Article Details

Introduction

A growing awareness that natural resources are limited and non-renewable is prompting the development and implementation of circular economy models, keeping resources in a continuous loop and minimizing waste, over the traditional linear economic model, which is based on resource extraction, consumption, and disposal. The European Commission (EC) highly recommends the adoption of circular economic approaches to address the challenges of environmental impact and resource inefficiency posed by the linear economic model [1] and suggests that economic benefits and a contribution to alternative energy production may also be realized [1]. Since about 60% of electric energy globally is produced from fossil fuels [2], which are widely recognized to be the main driver of climate change, the production of alternative energy from biowaste is being encouraged [3]. Alternative technologies, such as the production of energy from second-generation biomass, are being developed to produce energy from renewable resources [3]. Second-generation biomass refers to organic wastes and residues, solid and liquid municipal wastes, olive mill wastewater (OMW), or solid waste from olive mills. Waste may become landfilled or be spread over agricultural land. Pereira [4] reported that biosolids generated from sewage treatment plants are a good source of nutrients in chrysanthemum cultivation when added to the commercial substrate. OMW slurries can substitute for peat moss in horticulture.

Thermophilic anaerobic methanogenic digestion (TAMD) is a proven technology that reintegrates organic materials into the environmental cycle by producing biogas, ensuring optimal performance from both environmental and economic perspectives [5]. TAMD has been applied to various types of organic waste [6,7,8]. As an industrial solution, it addresses critical challenges such as environmental pollution and the recovery of natural resources, albeit requiring dedicated efforts to maintain stable and efficient operations. The design and economic viability of biogas plants depend largely on maximizing the use of biogas for energy generation and utilizing the heat locally through combined heat and power (CHP) systems. Additionally, the annual costs of a plant can be offset by marketing the treated digested slurry, derived from settled substrates, as a sustainable casing soil alternative [9]. A true mass and energy balance based on detailed financial inputs of all process outputs should be considered at the design stage of thermophilic anaerobic fermenter plants to treat OMW to achieve high plant efficiency.

Peatlands are critical ecosystems that serve as the largest terrestrial carbon sinks, host unique biodiversity, and regulate hydrological cycles. Peat extraction, however, has significant environmental consequences, including carbon release and ecosystem degradation. As global awareness of these issues grows, the demand for sustainable alternatives in horticulture has become urgent [10,11]. Based on experimental results and the analytical description of complex organic compounds, it is possible to develop models of energy and mass balances for the digestion of waste such as OMW [12]. Central full-scale OMW treatment plants that collect OMW from over 20 olive mills reduce harmful and hazardous impact on the environment. Integrated treatment plants, which combine the use of biogas for energy and heat and the sale of digested slurry as a replacement for peat moss, may help to cover treatment expenses and contribute to reducing climate change. In addition, the overall efficiency of such a project will be improved by the energy savings and replacement of peat moss. Thus, efforts are focused not only on realizing “OMW treatment”, but also on directly or indirectly enabling the generation of products to be used sustainably in horticulture. These efforts are in line with other efforts to replace peat moss [13], with TAMD as a commercial biotech process enabling organic materials to re-enter the environmental cycle. As an industrial process, TAMD may help to solve problems of environmental pollution and recovery of natural resources but needs special efforts for stable and efficient operation. The process design and economic efficiency of biogas plants presented herein is primarily related to the possible use of biogas to generate energy and local use of the heat by CHP generators, while selling the digested slurry after treatment as casing soil for horticulture in greenhouses. It presents the EU Green Deal strategy and a circular economy approach that can contribute to climate change mitigation through the reduction of CO2 emissions by reducing use of peat [10] as well as influencing soil health by stopping the distribution of raw OMW on land. It involves reducing the excavation of peat moss, which release vast amounts of stored carbon into the atmosphere, contributing to greenhouse gas emissions (10). Reducing reliance on peat moss in the horticulture sector is a critical step in mitigating these impacts.

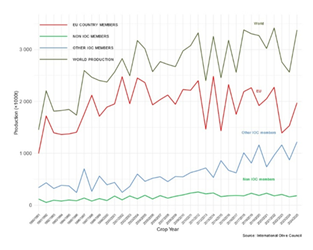

OMW production in the southern Mediterranean countries is considerable. According to official data and estimates from the International Olive Council (IOC) executive secretariat (Fig. 1)[14] world production for the 2024/25 crop year could reach 3,375,500 tons, an increase of 32% from the previous year. IOC member countries are forecast to produce 3,193,000 t, or 95% of the world total in 2024/25, an increase of 33% from the previous year. World consumption of olive oil could reach 3,064,500 t, an increase of 10% from the previous year.

We propose that OMW has remarkable potential for bioenergy production. OMW should be considered as part of an economic approach to promote a cleaner and more viable process for a sustainable future. The increasing use of olive oil in the world demonstrates opportunities for the sector’s development. The possibility of producing OMW-based energy is currently not fully exploited due to obstacles in cooperation between OMW and biogas producers, mainly due to a lack of full economic understanding. Consequently, the potential environmental and economic benefits are not achieved [15]. Improper disposal of OMW results in several environmental problems, including eutrophication of lakes and rivers, pollution of underground water and soil [16], and the emission of odor and greenhouse gases (GHG) to the environment. Despite these problems, OMW may be a valuable resource if incorporated into a circular concept. We propose new approaches focusing on digestion of the organic matter in a central location over the entire year (and not only during the olive harvest season) and reduction in polyphenol concentration, while recovering and reusing the process products to produce alternative energy (biogas) and as a substitute for peat moss in horticulture. Environmental and policy issues associated with olive oil production are specific to the Mediterranean countries, and regardless of location, these issues generally include application of OMW to land and potential discharge of pollutants (chemical oxygen demand [COD] and polyphenols) and pathogenic bacteria to surface and groundwater [17], and aerial emissions of ammonia, methane, pathogens, and odor [18]. As olive oil is traditionally produced by many small operators, the resulting wastewater is difficult to monitor and affects wastewater treatment plant (WWTP) utilities during the olive harvest season.

Proposed OMW treatment based on a pilot experiment

Treating OMW to protect the environment is complex, with no single ideal solution [19]. The proposed technology and methodology of treating OMW at a central location will be effective in reducing GHG emissions from olive oil production and enhancing olive mill productivity and the health of stakeholders in the villages. Rather than spreading OMW on land, we propose storing it in a controlled reservoir where gases are collected. This will result in: (1) reduction of GHG emissions since wastewater will not be released into natural waterways and the need to spread OMW on land will be minimized; (2) the breakdown of organic matter will produce biogas and generate electricity and heat by Combined Heat and Power (CHP) generators; (3) solid materials in the OMW will be used as topsoil in horticulture, replacing peat moss, thus reducing harmful peat excavation; (4) the recovery and reuse of treated water in agriculture will help cover the shortage of water for irrigation; and (5) the health of stakeholders in the villages will be improved and jobs for women may be generated. In the demonstration plant analysis presented herein, we estimate that 30,000 m3 will be collected at the central plant yearly, and will produce electricity (€218,009), heat (€107,136), and OMW slurry to replace peat moss (€9,000).

Materials and Methods

The present study was based on pilot-scale experiments conducted at MIGAL, utilizing two digesters (4 m³ each) to evaluate the thermophilic anaerobic digestion of OMW. Key performance indicators included biogas yield, digestate quality, and quality of the treated wastewater entering the WWTP utility stream. Economic modeling was based on a hypothetical centralized plant processing 30,000 m³ of OMW annually, with assumptions derived from pilot data. The full-scale implementation of TAMD using OMW as a substrate demonstrates a viable pathway to achieve high and stable biogas production. On the pilot scale, OMW is collected from local olive mills and transported to the MIGAL pilot facility, where it is initially stored in several reservoirs. After a few days of solid sedimentation, the OMW liquids are pumped to a coagulation/flocculation treatment plant for solid-liquid separation that employs nanocomposites to reduce the suspended solids [20]. The recovered solids are repurposed as a peat substitute. The liquid fraction is adjusted to pH 7 and fed into thermophilic anaerobic digesters (55°C), where it undergoes fermentation to produce biogas. Following anaerobic digestion, the effluent undergoes aerobic treatment in a series of four gravity-fed vessels, each aerated to enhance microbial activity. The final treated effluent is suitable for reuse in agricultural irrigation or to be dumped into the WWTP system. Here, we analyze the OMW-based biogas supply chain, i.e., the production of biogas from OMW by thermophilic anaerobic digestion. Based on the pilot operation, we present a theoretical business plan outlining the main variables affecting the cooperation dynamics among OMW producers and biogas utilizers. The OMW-based biogas supply chain is modeled through an economic analysis approach, identifying the technical and economic variables affecting the environmental and the economic benefits generated. The impact of the above-mentioned variables on the supplier-buyer relationships in the local region was assessed to foster cooperation based on the involvement of stakeholders in living labs (LLs) and to stimulate the production of renewable energy.

Results

Treatment of OMW by thermophilic anaerobic fermentation followed by aerobic polishing

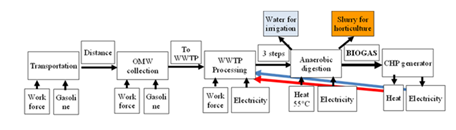

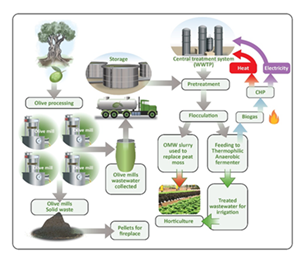

The functional unit of the supply chain is modeled as a process that transforms input from olive oil production into output of OMW produced during three-phase extraction. Based on discussions with stakeholders at LL meetings, we propose that the involvement of local stakeholders is crucial to the implementation stage, and that cooperation between local actors, including regulators, regional and national authorities, and investors, impacts this stage. The main production processes within the OMW-based biogas supply chain are shown in Figure 2 (modified from Yazan [21]). OMW is collected from olive mills, loaded onto trucks, and transported to a central biogas plant. The OMW is converted into biogas and digestate (an alternative to peat moss) by means of thermophilic anaerobic digestion, whereby microorganisms break down the biodegradable material in the absence of oxygen [22]. The biogas produced is then used for CHP generation to produce electricity and heat for local use.

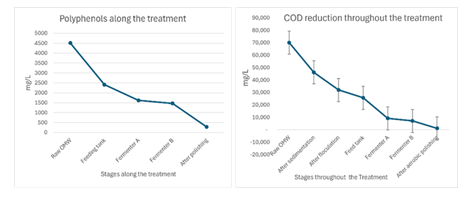

Accordingly, the following main steps are considered: OMW collection from village mills, transportation to the WWTP, storage of OMW for the entire year (in a pit with a cover to collect the gas emitted), an initial stage of flocculation/coagulation for clarification with nanocomposites [23], separation of the precipitate, thermophilic anaerobic digestion, and an aeration stage for polishing (with a suggestion to use the biogas for energy and heat production, and the slurry and treated wastewater for agriculture). Each step receives a main input, with some producing a main output. All outputs are physical products, except for the transportation process, which is the distance covered between the OMW and biogas producers. There are four primary inputs (gas/oil, workforce, electricity, other biomass), biogas gases (CO2, CH4), and three value-added by-products that can be sold (solid digestate, electricity and heat to be used by the WWTP, and treated wastewater for irrigation). COD measured at the pilot scale was reduced by 93% and the polyphenol content was reduced by 91% after the aerobic polishing stage (Figure 3). Using heat and electricity from biogas has already been shown to offer a sustainable method to reduce fossil fuel use, lower greenhouse gas emissions, and convert organic waste into valuable energy [6, 22]. Biogas provides a reliable, renewable energy source that supports local energy independence and waste management. The use of the OMW slurry from the process is innovative.

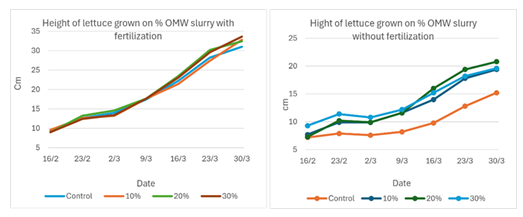

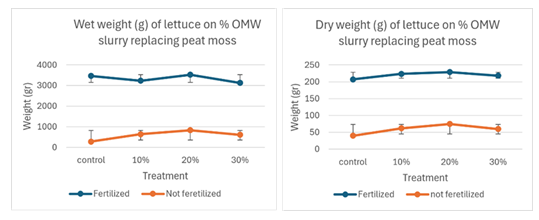

Use of OMW slurry in horticultureIn a comparative study of romaine lettuce (Lactuca sativa) cultivation, peat moss in regular horticulture soil, was partially replaced with an OMW-derived digestate: 10%, 20% or 30% of the peat were replaced with OMW slurry. The research was carried out in a screened greenhouse using 3-liter pots equipped with a drip irrigation system, with remote control of irrigation rate and duration, and dosage of nitrate and liquid potassium fertilizer. Sampling of leachates and chemical analysis of the leachates was performed to examine the need for fertilization of pots in which peat was partially replaced by OMW slurry. Leaf length was measured weekly to assess growth rate and, at a later stage, plant diameter. At the end of the experiment, the resulting biomass was weighed, the wet weight of the plants was measured after 60 days of growth, and dry weight of the plants was measured after drying at 65°C for 3 days. Crops grown with OMW slurry as an alternative to peat moss were shown to have a yield equal to that obtained with conventional horticulture methods. Plant height was monitored throughout the growing season. The data presented below suggests minimal variation between treatments. A slight reduction in growth rate was observed when 30% of the peat was replaced with OMW slurry. Growth metrics remained comparable, particularly with added fertilization, suggesting the viability of the digestate as a soil amendment (Figure 4).

Results of the wet and dry weight of lettuce grown in pots with OMW slurry are presented herein.

Replacing 10%, 20% or 30% of the peat with OMW slurry was comparable to the commercial control used in horticulture (drip irrigation with Shafer 5-3-8 fertilizer [including microelements]), while a drop in growth after three weeks without the addition of fertilizer was observed, leading to the conclusion that over three weeks, the OMW slurry effectively released the essential nutrients, which were later reduced. Results of the wet and dry (at 65°C for 3 days) weight of lettuce are presented in Figure 5. There was almost no difference between the control and the soil mixtures in which peat was replaced by up to 30%. A 100% survival rate for the lettuce plants was observed during the 60-day growth period prior to harvesting. The growth rates showed similar trends in all pots that were irrigated with fertilizers, even where 30% peat was replaced by OMW slurry (Fig. 4). When the lettuce plants were irrigated without the addition of fertilizers, there was no difference in growth rate, which decreased sharply in a similar pattern in all pots, although better growth rates were observed when peat was replaced with OMW slurry. We harvested all the lettuce plants after 60 days, when the leaves began to close and the lettuce was ready to market, and weighed them immediately for wet weight. Thereafter, they were dried for 3 days in aluminum trays in a heater at 65°C, after which the dry weight was measured. Figure 5 shows that there was almost no difference in the dry weight of the lettuce when 10-30% of the peat was replaced. The dry weight of lettuce grown without fertilizer was similar, although much lower, indicating the need for fertilizers for growth. Better growth was observed when OMW replaced peat. It is obvious that fertilization is needed for plant growth, and there is a distinct difference between the growth of lettuce with or without additional fertilization during irrigation (once a day, for 20 minutes, with or without fertilizers, 60 ppm of Shafer 5-3-8 +1), but some improvement can be seen in the first period of growth in the OMW slurry soil. Wet and dry weights of lettuce revealed that there is almost no difference in growth rate when peat is replaced by OMW slurries, suggesting that peat can be successfully replaced by OMW slurry in potting substrates, and that reducing fertilization during the early stages of growth may be possible due to the nutrient content provided by the addition of slurry from oil mill effluents.

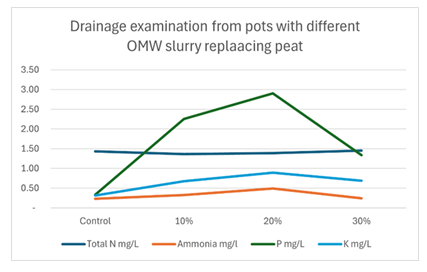

Leaching of liquids under the pots was examined for the different nutrients needed for lettuce growth. Nutrient analysis was conducted after three weeks of growth, by which time significant leaching had occurred due to prolonged irrigation. Figure 6 shows total nitrogen, ammonium, phosphorous, and potassium in the drainage water of the pots in which OMW slurry partially replaced peat. The results support the conclusions from the growth experiments that replacing peat with OMW slurry contributes to the nutrient supply to the plants.

Economic calculations

Here, we applied the economic model to a theoretical economic case, assuming fixed costs and prices for the regional scale “OMW to biogas” plant. The growing demand for sustainable wastewater treatment solutions has led to the exploration of integrated resource recovery approaches that enhance both environmental and economic performance. One promising strategy involves establishing the proposed OMW treatment full-scale plant within wastewater treatment plant (WWTPs) sites. This combined treatment and the approach presented herein align with circular economy principles by simultaneously addressing waste management challenges, promoting renewable energy generation, and the recovery of valuable nutrients.

In the context of this study, a cost-benefit analysis was conducted to evaluate the economic viability and environmental impact of the circular economy of treating OMW as detailed above. This analysis considered the initial investment in the recovery process, operational costs, and the market value of the energy, heat, and OMW slurry as an alternative to peat moss, without giving value to the treated wastewater that can be used for irrigation and saving water for agriculture. It did not consider the economic value of the intangible reduction of GHG and benefits to citizens, and the environmental benefits derived from diverting polluted wastewater from landfills. The analysis is critical in assessing the overall sustainability of the proposed circular economy approach, highlighting the trade-offs and synergies between economic efficiency and environmental stewardship.

Complementing the economic perspective, a lifecycle assessment (LCA) will be conducted to evaluate the environmental implications of OMW digestion. The LCA follows a cradle-to-grave approach, encompassing the collection and transport of OMW, its digestion at thermophilic temperature, energy recovery from biogas, and the fate of the digestate and treated effluent, presented with low cost for the digestate and no revenue from the treated wastewater after the aeration polishing stage. Environmental impact categories such as global warming potential (GWP), eutrophication, fossil energy depletion, and water use are not given any additional costs.

In the base scenario, we assumed processing of 30,000 m3 of OMW collected from nearby olive mills over an entire year and an average transportation distance of 20 km between the village olive mills and the WWTP, where a regional-scale biogas plant would be located. Values of technical parameters are extracted from the pilot experiment (two digesters of 4 m3 each and a full process from receiving the OMW, thermophilic fermentation, and an aeration stage in four continuous vessels in which the liquids flow gravimetrically from one to another and are aerated for polishing) that operated for approximately two years. Our experience showed different COD content for OMW from different mill processes and olive tree species, which reached up to 130,000-150,000 mg/L, so an average value was used. The solids content is about 3%, of which 83% is organic matter. From one cubic meter of OMW, it is possible to produce 12 m3 of biogas and 1.0 t of digestate. The cogeneration process from 1 m3 of wastewater can produce 30.28 kWh of electricity and 5.95 kg LPG of heat (based on 20% energy for self-consumption) [24]. Based on the results from operating the pilot plant for two years, we estimated the work force required and the cost-effective practices, the associated production costs of the materials needed for the coagulation/flocculation pretreatment of the OMW wastewater (solid-liquid separation) used in the present case, which included 1% polymer/clay nano-composite (NC 24) and 40% ZETAG 9088 [23], and the equipment costs (scaled up from the equipment used in the pilot) and based on previous experience in treating cow manure [6]. We are also exploring other cost-effective alternatives for clarification methods, as well as the use of equipment to break down the polyphenols, but we have not yet included these technologies in the theoretical economic analysis. The environmental impact, not directly accounted for in the cost, is significant in a broader sustainability context, and favors the use of recycled biowastes, which aligns with the goals of a circular economy by minimizing waste and reducing reliance on non-renewable resources. The integration of a plant to treat OMW next to a wastewater treatment plant has the potential to enhance biogas utilization, offset fossil fuel-based energy consumption, and reduce greenhouse gas emissions. However, the success of this approach depends on the careful management of risks, including feedstock variability, pathogen control, and effective digestate utilization. The findings of this study aim to inform decision-makers, engineers, and environmental planners about the benefits and limitations of adopting OMW central digestion systems that leverage olive mill residues, ultimately contributing to more resilient and sustainable wastewater treatment infrastructure, while protecting the WWTP from the pollutant OMW when it is flushed to the sewage system.

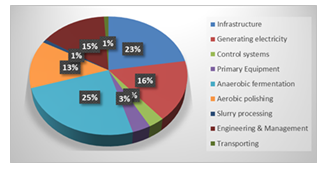

Table 1 presents the theoretical results of an economic analysis of treating OMW from 30 mills at a central location, based on the figures we have from the small pilot plant. Figure 7 shows the breakdown of costs of the different components of the full-scale DEMO system.

It is important to mention that for a plant to be economically successful, the collaboration of the different partners in the region is important. This is in line with the economic analysis by Esposito et al. [25], in which it was concluded that positive economic results largely stem from an approach that promotes collaboration between biogas companies and renewable energy communities.

Furthermore, the approach presented by Cattaneo et al. [26] emphasized that integrating renewable energy with the regional communities is crucial for its success, with considerable potential for the integration of biogas plants into the farm environment. Although this is a challenge for small- and medium-sized farms, it could bring energy self-sufficiency and economic surplus and would transform weaknesses and threats into opportunities.

Table 1: Input-output table of the OMW-based biogas central demonstration plant.

|

Net present value (NPV, 10 years) |

12,39,234 |

|

Internal rate of return (IRR, 10 years) |

42.49% |

|

Payback period (years) |

3.26 |

|

Breakeven price for waste disposition (Euro/ton) |

14.44 |

Table 2: Economic indicators (Euro).

From these calculations, it would appear that a central plant is economically feasible.

Circular business model scenario

Since bioenergy supplier and buyer networks are characterized by a notable level of uncertainty, we present the approach of activating regional Living Labs and the role of variables influencing chain performance and decisions to cooperate on OMW treatment. There are two actors in an OMW-based biogas supply chain: the OM owners and a bioenergy producer, hopefully a local WWTP that is affected by OMW released into the sewage system and is a customer of electricity and heat. As an addition to the base scenario, we assume that there are local farmers who use peat moss as topsoil in greenhouses, meaning that the digestate produced by the bioenergy producer can be used by the farmer in his greenhouse to replace expensive peat moss. We evaluate two scenarios: (i) non-cooperation, in which the OM owners are subject to penalties and are only ready to enable the central plant to take the OMW and pay equal costs to their past distribution on land; and (ii) cooperation, in which the OM owners and the central treatment plant are working together. In the first scenario, the olive mill owner produces OMW, which is dumped into the sewage system, and is subject to penalties, or transports and spreads the OMW onto soil himself or via a sub-contractor. The biogas plant is not part of the business (model). In the second (cooperation) scenario, the olive mill owner produces OMW, which is sent to the biogas plant. The biogas plant produces biogas (used for electricity and heat production) and digestate, which is sold to farmers or on the open market. In some cases, the owners take the lead in establishing the central plant and providing WWTP with energy and heat. The OM owner is also a farmer and has greenhouses and can use digestate as a substitute for peat moss. In the case of cooperation, the OM owners or local farmers are confronted with a decision of whether to be involved in energy production. In traditional production systems, OM owners and farmers are not involved in energy production because they are mainly concerned with olive oil production or horticulture. So, what motivates the actors to cooperate? First, from an economic perspective, olive oil production results in high quantities of OMW that exceeds the capacity of the owner to treat it properly. Second, regulatory constraints on OMW flushed into the sewage system resulted in the owner paying penalties or dealing with transporting the OMW to be spread on land, with a subsequent environmental effect on the village. Both situations influence the economic performance of OM owners, leading to high OMW disposal costs and an effect on their families. The bioenergy producer, on the other hand, has the advantage of producing a by-product to gain higher added value, i.e., digestate and treated wastewater for irrigation (flushed into the regular system of WWTP that supplies treated water for irrigation).

From an operational perspective, using the digestate instead of peat moss in greenhouses directly contributes to plant growth, serving as a substrate and contributing fertilizer, potentially reducing the amount of fertilizer applied. Digestate has the remarkable advantage of influencing climate change as well as reducing costs for the farmer. To understand how uncertainty affects cooperation among actors, we identified several variables and investigated their impact on the implementation of the supplier-buyer relationship in the local OMW region. These variables included critical operational, technical, and economic variables of the central plant, which receives OMW from the mills and generates electricity, heat, digestate, and treated wastewater for irrigation. These variables are critical for the operational efficiency and economic performance of an OMW-based biogas supply chain and on rural economic development, as well as on the relationship between owners and regional authorities. The quantity of OMW is determined by plant scale in the cooperation scenario, and on the “products” used locally. Transportation distance has significant impact as OMW has very low value, consequently influencing transportation costs. Variations in OMW due to olive tree species and mill production methods, and the resulting organic matter, are critical for the biogas and digestate yields. OMW discharge cost is also a critical variable, particularly when the bioenergy producer is a unique alternative to OMW discharge. Accordingly, we assume that the biogas producer does not charge more than the discharge cost to the OM owner in the cooperation case and the OM owner does not ask for payment once he realizes that the energy producer is earning money

Discussion

We have presented the importance of co-designing the system and analyzing the environmental impact by local Living Labs (LL) for a successful circular economy that enhances regional development. The involvement of stakeholders at the local LLs will ensure adherence to relevant environmental standards and legal requirements, and identify limitations related to the technology. The co-design of LLs is about creating a collaborative, real-world innovation environment where diverse stakeholders work together to develop, test, and refine solutions regarding the proposed development. The aim is to ensure that the solutions are user-centric, effective, and sustainable in real-life contexts. By using a co-design approach, the LLs become a space for innovation that reflects the needs and aspirations of the people it is intended to serve, as well as the environment. Consultation with the stakeholders will define OMW pollution hazards and their effects on the environment and WWTP utilities. The environmental impact of OMW contamination in the sites proposed must be determined. Stakeholders can determine the most appropriate place to establish a plant. The following key factors should be considered by the diverse stakeholders:

Proximity to olive mills: Accessibility: Selection of a location within a reasonable distance from multiple olive mills to minimizing transportation costs and emissions.

Logistics: Ensuring the site is accessible via existing road networks to facilitate the efficient collection and transport of OMW.

Environmental considerations: Hydrogeology: Avoiding areas with high groundwater tables or permeable soils to prevent contamination.

Ecological sensitivity: Steering clear of protected natural habitats, wetlands, and areas with endangered species.

Gas emission: GHG emissions at olive mills differ greatly from those at the treatment plant since there is no free distribution of OMW on land or soil, the gases are collected at the reservoir, and the biogas produced is used at a CHP generator, although some CO2 is produced.

Land use and zoning: Compatibility: Ensuring the site aligns with local land use plans and is zoned for industrial or waste treatment activities.

Buffer zones: Maintaining adequate distance from residential areas to minimize potential nuisances such as odors and noise.

Infrastructure availability: WWTP utilities: Assessing the possibility of locating the plant at WWTP to receive essential services, and has the need for electricity and heat, use of the treated water for irrigation, and telecommunications.

Socioeconomic factors: Community acceptance: Engaging with local communities to address concerns and gain support for the project.

Regulatory compliance: Permits: Ensuring the site meets all local, regional, and national regulations for OMW treatment at the facilities.

Impact of OMW quantity

According to the local situation (and the effect of intercropping on olive production on alternate years), OMW quantity notably affects cooperation benefits. For small- and medium-size OMs, the benefits are negative. For the bioenergy producer, the larger the scale, the greater the benefits from cooperation. Numerous researchers have already shown that building a plant at the site of an olive mill is not profitable, especially since the harvest season is 3-4 months and operating any system to treat OMW is expensive. To summarize cooperation activity, it is profitable for a large-scale operation if owners pay the same amount for discharge as for spreading the OMW on land, regardless of the value of other variables.

Impact of OMW price and OMW quantity

When the OM owner obeys regulations and pays the sub-contractor to distribute the OMW on soil, his costs are at least 15 €/m3 or he pays the bioenergy producer to receive its OMW (OMW price =15 €/m3). In such a case, the benefits for the large-scale bioenergy producer are the highest since there is a chance of having a steady market. When the bioenergy producer pays the OM owners based on successful sale of all the “products”, the benefits for the bioenergy producer are smaller, but still positive.

Impact of transportation distance and OMW quantity

According to the program for a central plant that receives OMW from several OMs, the shorter the transportation distance, the greater the benefits arising from cooperation. The impact increases with increasing olive mill size and plant scale.

Impact of OMW discharge cost and OMW quantity

The central plant benefits depend on OMW discharge cost, and the penalties enforced on OM by regulators (and in some scenarios also on subsidies from the government or the Water Authorities). If regulation enforcement is high, the OM revenues in case of non-cooperation decrease because the remaining amount of OMW must be disposed of. On the other hand, the bioenergy producer is not affected by the discharge cost if there is a contract with the owners on the level of payment per m3. However, depending on the case, OMW discharge costs might give the bioenergy producer an idea of the OMW price that the OM owner must pay.

Impact of OMW discharge cost and OMW price on benefits

We present the combined effect of OMW discharge cost and price on cooperation dynamics for a large-scale plant, having shown in preceding analyses that large-scale cooperation is more advantageous. The OM owner has the highest benefit when OMW discharge cost is 15 €/m3 and when the central plant earns money from the “products”, the bioenergy producer pays owners a share of the profit while receiving the OMW. The benefit to the bioenergy producer peaks when the OMW price is 15 €/m3 (and he does not pay the OM owner to receive OMW), regardless of the discharge cost.

Cooperation is always profitable for a bioenergy producer if owners pay to transport their OMW (15 €/m3) to a central plant and there is a local customer, such as WWTP, who will use the electricity and heat, and for the slurries to replace peat moss and treated wastewater to be used for irrigation. It is important to note that OMW quantity and energy and the price of heat have the strongest impact on cooperation dynamics, because they significantly affect the benefits for both sides. The use of the digestate is important for aspects of climate change, as it will reduce peat moss excavation and benefit the farmers if the central plant owners do not increase the costs too much.

Our results provide a better understanding of the potential of cooperation among supply chain actors to develop a local circular economy business model. Such a mechanism provides effective use of existing local resources, particularly when the supply is high and the bioenergy plant uses the advantage of economies of scale and can use or sell all the “products”.

Based on the results of our analysis, cooperation between OM owners and the WWTP, or investors, to erect a full-scale system can benefit both the actors and the environment. However, when the total benefit lies more with the central system, OM owners might request payment for the OMW instead of paying for transportation, especially if regulations and penalties on discharge of OMW are not enforced. To foster cooperation, benefits could be shared between the two sides. Benefit-sharing schemes should be further investigated in future research.

The cooperation scenario, involving LLs, has other significant technical, environmental, and social advantages. In comparison to untreated OMW, thermophilic anaerobic digestion of OMW provides multiple additional benefits, such as decreasing methane emissions and odor, as well as increasing hygiene in villages, and may increase jobs and regional development.

Conclusions

The sustainable OMW-biogas circular model presented herein is technically and economically viable. It transforms a pollutant into renewable energy, topsoil for horticulture, and irrigation with treated wastewater. With policy support, it strengthens local economies and environmental health. The research provides an economic approach to the environmental challenges caused by OMW contamination of streams and groundwater, particularly from small-scale mills that lack local treatment facilities. The use of thermophilic anaerobic digestion and a polishing aerobic stage while using the slurry as an alternative to peat moss and the treated wastewater for irrigation is promising. Using a substitute for peat moss in horticulture will contribute to the reduction of GHG caused by its excavation and benefit climate change. These efforts contribute to healthier ecosystems and a more sustainable bioeconomy.

Acknowledgment

The pilot project was funded in part by the Middle East Regional Cooperation (MERC) Program, Grant No. SIS700XXGR0017, from the United States Department of State and the United States Agency for International Development, and by the Israeli Ministry of Energy Grant No. 222-11-097. The opinions, findings, and conclusions stated herein are those of the authors and do not necessarily reflect those of the United States Department of State or the United States Agency for International Development or those of the Israeli Ministry of Energy.

References

- European Commission (EC) Circular economy action plan (2025).

- IEA Renewables, 2024. https://www.iea.org/energy-system/renewables

- Albino V, Fraccascia L, Savino T. Industrial symbiosis for a sustainable city: Technical, economical and organizational issues. Procedia Eng 118 (2015): 950-957.

- Pereira F, Oliveira U, Andrade M, et al. Biosolids as an alternative source of nutrients in chrysanthemum cultivation. Nature Sci Rep 14 (2024): 20539.

- Schnidrig J, Souttre M, Chuat A, et al. Between green hills and green bills: Unveiling the green shades of sustainability and burden shifting through multi-objective optimization in Swiss energy system planning. J Environ Manage 370 (2024): 122537.

- Steiniger B, Hupfauf S, Insam H, et al. Exploring Anaerobic Digestion from Mesophilic to Thermophilic Temperatures - Operational and Microbial Aspects. Fermentation 9 (2023): 798.

- Wilson CA, Murthy SM, Fang Y, et al. The effect of temperature on the performance and stability of thermophilic anaerobic digestion. Water Sci Technol 57 (2008): 297–304.

- Marchaim U, Kostenberg D, Epstein E. Auxins and phenols in anaerobic thermophilic digestion of coffee wastes and their synergistic effect in horticulture. Mikrobiologiya 66 (1997): 706-711.

- Levanon D, Musaph S, Danai O. Nutritional and ecological aspects of the use of organic wastes for mushroom casing. Mushroom Inf 5 (1988): 13-14.

- Restrepo A, García J.’ Moral R, Vidal F, et al. A comparative cost analysis for using compost derived from anaerobic digestion as a peat substitute in a commercial plant nursery. Cien Inv Agr 40 (2013): 253-264.

- Hutchinson JN. The record of peat wastage in the East Anglian Fenlands at Holme Post, 1848-1978 A.D. J Ecol 68 (1980): 229-249.

- Fleyfel L, Matta J, Sayegh N, et al. Olive mill wastewater treatment using coagulation/ flocculation and filtration processes. Heliyon 10 (2024): e40348.

- Meng X, Wang Q, Lv Z, et al. Novel seedling substrate made by biogas residues. Ind. Crops Prod 184 (2022): 115028.

- IOC report. World Market of Olive Oil and Table Olives (2024).

- Zhang Y. Circular economy innovations: Balancing fossil fuel impact on green economic development. Heliyon 10 (2024): e36708.

- Khdair A, Abu-Rumman G. Sustainable environmental management and valorization options for olive mill byproducts in the Middle East and North Africa (MENA) region. Processes 8 (2020): 671.

- Kapellakis I, Tzanakakis V, Angelakis A. Land application-based olive mill wastewater management. Water 7 (2015): 362-376.

- Yaakoubi A, Aganchicha B, Meddicha A, et al. Land spreading of olive mill wastewater (OMW): Biodegradation of organic matter and polyphenols in soil and effect on the activity of the total soil microflora. Water Pract. Technol 19 (2024): 298-310.

- Shabir S, Ilyas N, Saeed M, et al. Treatment technologies for olive mill wastewater with impacts on plants. Environ Res 216 (2023): 114399.

- Yazan DM, Garavelli AC, Messeni Petruzzelli A, et al. The effect of spatial variables on the economic and environmental performance of bioenergy production chains. Int J Prod Econ 131 (2011): 224-233.

- American Biogas Council. What is Anaerobic Digestion? Promoting the Anaerobic Digestion and Biogas Industry. (2014).

- Kabeyi M, Olanrewaju O. Biogas production and applications in the sustainable energy transition. Hindawi, J. Energy (2022)

- G Rytwo. Method for treatment of industrial organic effluents with nanocomposites of a polymer adsorbed on anchoring particles. Provisional Us patent application 61/500,296, June 2011.

- Navaratnasamy M, Edeogu I, Papworth L. Agriculture Stewardship Division, Alberta Agriculture and Rural Development. Economic Feasibility of Anaerobic Digesters. AGRI- FACTS. Agdex No.768 6 2008.

- Esposito L, Vecchio C, Cattaneo G, et al. Addressing challenges and outcomes in the biogas sector: An analysis of efficiency, economic savings, and environmental impacts using an advanced SWOT Model. Energies 16 (2023): 7413.

- Cattaneo G, et al. Addressing challenges and outcomes in the biogas sector: An analysis of efficiency, economic savings, and environmental impacts using an advanced SWOT model. Energies (2023).

Journals List

© 2016-2026, Copyrights Fortune Journals. All Rights Reserved